Some glass reprocessors say they are now willing to pay more for material while the PRN price remains high.

On the other hand, others say that due to the “volatility” of the market they are unlikely to pay “much more” in the short term. Currently, glass is only worth “a few pounds extra” per tonne.

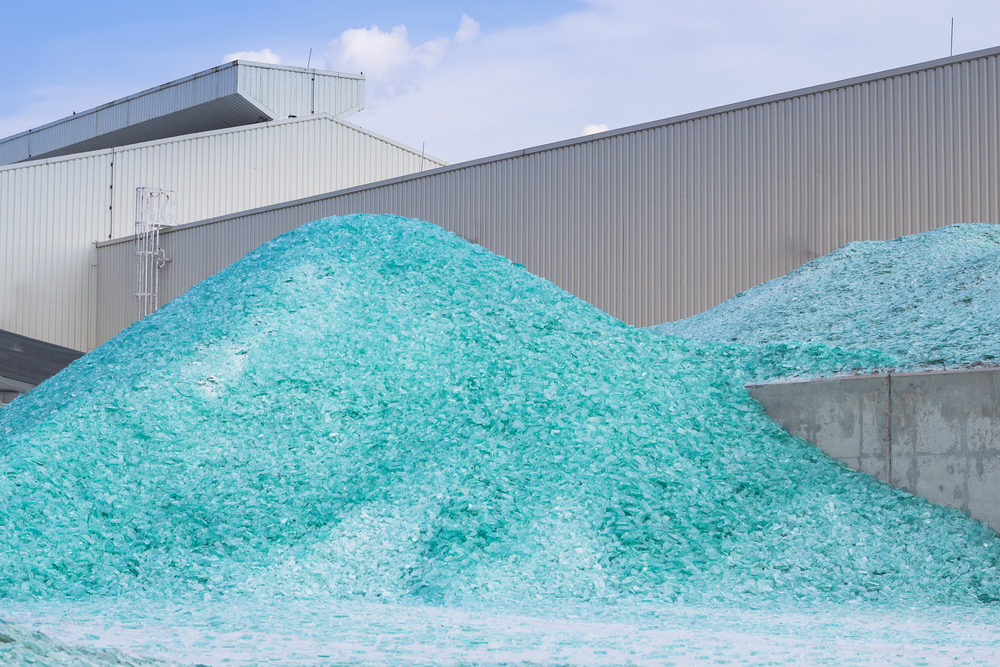

Some in the sector suggest that prices could rise further as there is also a “small shortage of cullet” to make bottles in the UK.

Remelt and ‘other’

Glass PRNs can be purchased either as remelt or as ‘other’, which covers glass that goes towards aggregate. Remelt is seen as the more circular solution but requires more expensive processing, hence the split.

Provisional figures published by the Environment Agency for the first half of 2022 show that only around 42% of the glass aggregate PRNs needed to meet the expected obligation have been issued (see letsrecycle.com story). Glass remelt stands at around 50% of the way towards the expected obligation.

According to compliance specialists, the price of glass remelt PRNs rose from between £45-£95 per tonne in January to £120-£150 in August. The price of glass aggregate PRNs rose from £10-15 per tonne to £100-130 in the same period.

Market

One reprocessor with a significant share of the market told letsrecycle.com it would be “the tightest year ever” in terms of meeting obligations. “The signs were there last year that everything would be tough this year,” they said. “Remelt is tight, ‘other’ is in shortfall.”

They suggested material which usually went for remelt was being diverted to make up the aggregate shortfall. “You can stockpile remelt material,” they said, “but you don’t stockpile aggregate.”

Currently, some reprocessors are even willing to pay to take material with a greater level of contamination from material recycling facilities (MRFs), for which they often receive a gate fee. A significant proportion of this material will be used to make aggregate.

Another reprocessor with plants across the UK suggested they were “happy” to pay more for glass because they were making back their costs via the PRN.

However, a rival recycler suggested a “cautious market” anticipating that the prices may still fall was not yet willing to pay much more for material.

Carry-over

A smaller volume of ‘carry-over’ material than in previous years is said to be a significant factor contributing to the lack of progress towards the targets.

Less glass was collected from pubs and the rest of the hospitality sector than usual in 2021, meaning there was a smaller tonnage of carry-over into 2022 (see letsrecycle.com story).

The Environment Agency carried over 26,429 tonnes of glass other PRNs and 80,657 tonnes of glass remelt PRNs from 2020 to 2021. By contrast, just 16,619 tonnes of glass other PRNs and 64,555 tonnes of glass remelt were carried into 2022, meaning more glass needs to be recycled this year to make up the shortfall.

Energy cost

Sandeep Attwal, group procurement manager at packaging waste compliance scheme Ecosurety, suggests there is a “high risk” that “any further slowdown” in the recycling and recovery of glass packaging waste in the second half of the year will lead to “significant increases” to the cost of compliance for producers.

“Glass recycling volumes have remained low for the first half of the year, and this has mainly been impacted by the diminishing supply of glass aggregate,” Ms Attwal said in a blog post.

She also suggested: “The glass remelt sector have suffered with significant increases in the cost of energy, hence the exponential rise in costs of recycling evidence.”

Shortage

Though experts suggest the increased prices are driven almost entirely by the value of the PRN, it is believed there is a “small shortage” of cullet for bottle making in the UK.

Several reprocessors expressed concerns that more material is being exported from the UK, leading to the domestic shortage.

Exporters can issue PERNs on up to 98% of the material they ship, one domestic reprocessor said, allowing them to take advantage of the high prices and “line their pockets”. By contrast, the reprocessor said, domestic recyclers only issue PRNs on around 70% of the material they process, given levels of contamination.

In addition, unlike domestic recyclers, exporters do not incur labour or energy costs.

The price of PRNs has increased for all materials across the board, with the value of paper PRNs soaring to a 20-year high (see letsrecycle.com story).

Subscribe for free