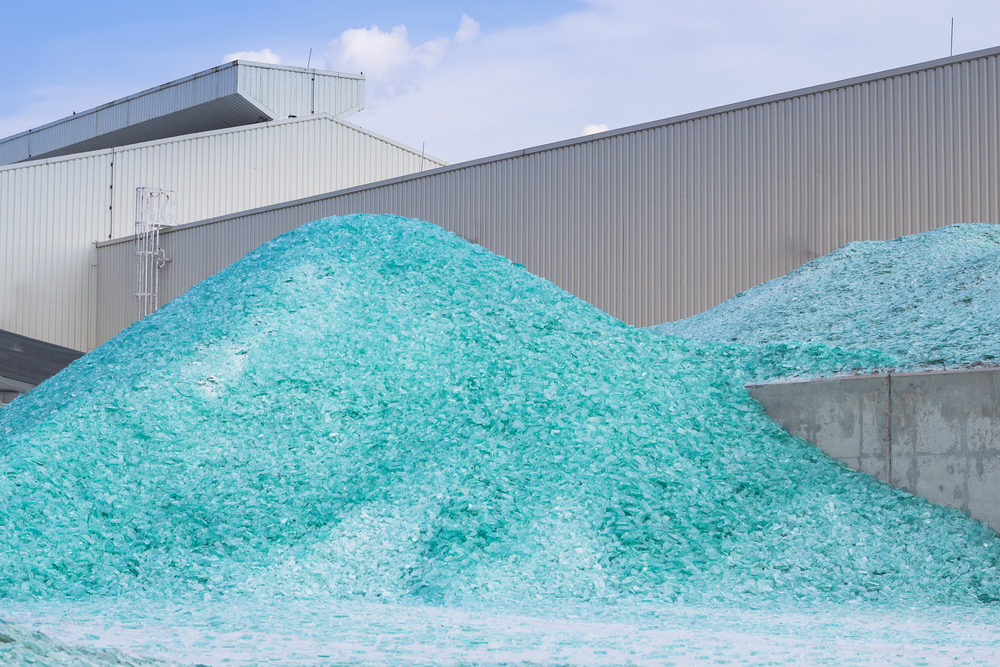

The funding will go to Sheffield University’s Centre for Cement and Concrete to carry out two major investigations into the potential for using glass cullet as a high-value ingredient in concrete. WRAP is providing 947,000 of the total funding, with a further 140,000 of in-kind funding from the University.

It is hoped the projects – known as ConGlassCrete I and ConGlassCrete II – will lead to waste glass being used in a wide range of products. The projects are especially focused on developing cullet as a decorative, exposed or polished aggregate finish in bespoke concrete products, and as a high-value cement-like material that will reduce consumption of Portland cement.

Other potential applications being explored include fibre-reinforcement, or general low-value aggregate, for concrete.

WRAP says that “this important R&D; work is a response to EU pressure to increase reuse of container glass, and comes ahead of legislation on recycling car windscreens and laws governing end-of-life vehicle glass, light bulbs and glass fibres.” And the organisation notes that “it is also likely that future waste legislation will force the glass and construction demolition industries to address the issues of waste plate glass.”

Two projects

Among the aims of the ConGlassCrete I project, (which focuses on mixed container cullet), is the attempt to develop markets for recycled container cullet in the concrete products industry and to facilitate additional accredited re-processors for Packaging Recovery Notes (PRNs).

The second project will look at the scope for market opportunities for businesses in the flat glass, end of life vehicle glass, glass fibre and light bulbs industries.

The projects – which will run until March 2004 – have won support from a good proportion of the UK’s pre-cast concrete industry and research and certification bodies. They are also being backed by the cement and related materials industries, environmental bodies, waste glass producers, collectors and processors, and producers of pre-cast and ready-mix concrete.

Steering committee

Members of the ConGlassCrete project steering committee include: WRAP (funding), Valpak, British Glass, Glass-Technology Services, Mac-Glass Recycling, Northern Cullet, Wyre Waste Glass, Owens-Corning, Wales Environmental Trust, Business Environmental Trust, Chris Coggins, BCA, UKQAA, BRE, BRE Certification, Appleby Group, Aggregate Industries UK, Conways Concrete Products, CRH Group (Forticrete), H&H; Concrete Products, Marshalls Mono, Stowells Concrete, Tarmac Group and Trent Concrete.

Subscribe for free