After a three-year period of “intensive” assessment, RMC Materials has achieved the official endorsement of the scheme for its “Glasphalt” product, which contains up to 30% of recycled glass in place of primary aggregates.

The HAPAS certificate means highway construction companies will see the product as suitable for use on all roads and related works – including principal and trunk roads – without carrying out their own approval process.

RMC Materials technical manager John Lay said Glasphalt has now been proven to perform equally well as equivalent asphalt material containing natural aggregates from quarries.

He said: “HAPAS approval of Glasphalt is great news and means it should now be easier for the product to be specified. The hope now is that Glasphalt will be specified more widely on major road resurfacing works throughout the UK.”

Valpak

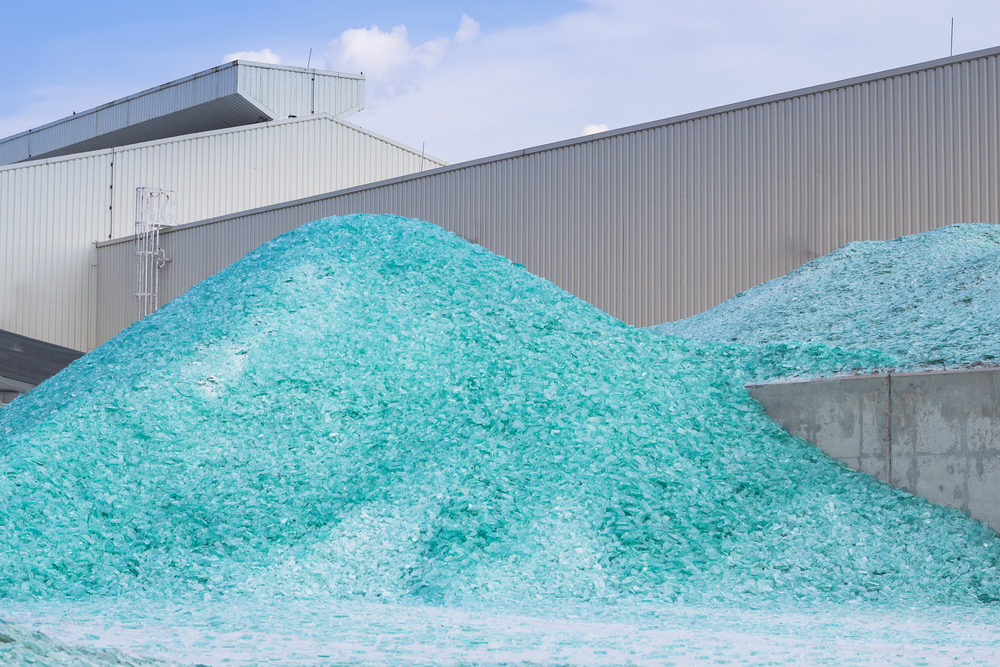

Glass used in the RMC resurfacing material is supplied by the packaging waste compliance scheme Valpak from bottle banks and central refuse points. Glass is crushed and screened at RMC's asphalt plants before being mixed with bitumen and fresh aggregates to produce Glasphalt.

So far, the product has already been used to resurface a worn carriageway on the M6 in Cheshire and on the M50 in Gloucestershire.

The Glasphalt product is part of an important alternate market for the recycled glass that cannot be used by container manufacturers in the UK because of this country's “oversupply” of waste green glass.

RMC's new GipoCombi crusher will process over 100,000 tonnes each year into new aggregates |

At the moment about 214 million tonnes of aggregates are used as a raw material for the construction industry, with about 50 million tonnes of this coming from recycled and secondary sources.

RMC purchased the UK's first GipoCombi RC 100 C mobile crushing and screening unit this month for use in the company's recycling centres in Norfolk and Cambridgeshire. The crusher was funded through a 111,000 grant from WRAP, the Waste and Resource Action Programme.

In its first year the plant will crush about 100,000 tonnes of material, the company believes, including glass, waste concrete and asphalt. This could rise to 150,000 tonnes a year in future.

Subscribe for free