The Sports Turf Research Institute found that replacing traditional sand on the golf course with sand derived from recycled glass improves the chances of those unfortunates drawn to the bunker.

The two-year project found that the recycled glass sand provides a better performance level with a firmer footing underneath. For golfers, it means less plugging of the ball, a steeper angle of repose and reduced slumping, WRAP said.

Laboratory tests carried out during the trial showed that the recycled glass conformed to all necessary performance requirements, it said, and is capable of complying with United States Golf Association specifications. WRAP said the glass-sand also proves beneficial for greenkeepers when used as a top dressing around divots, as it can blend into the ground better than traditional sand.

Andy Dawe, WRAP's materials sector manager for glass, said: “The trial undertaken by the STRI has been very successful, confirming that recycled glass derived sand is a quality alternative to traditional sand.

“At the same time, it offers greenkeepers a sustainable, quality product, as well as a way to demonstrate their environmental awareness and responsibility,” he added.

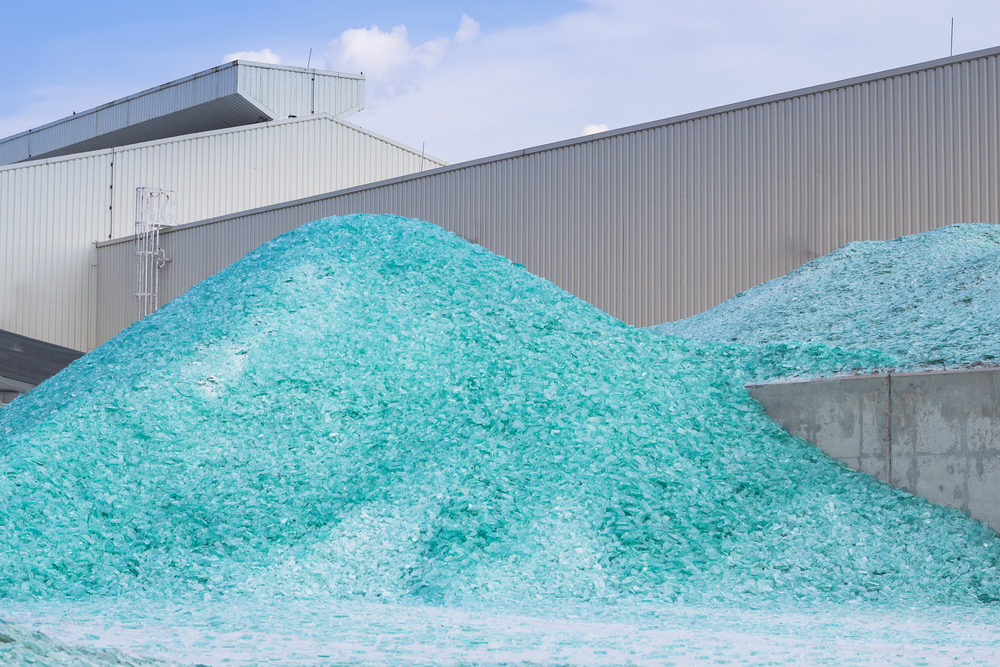

WRAP – the Waste and Resources Action Programme – has targets to directly facilitate the recycling of an additional 150,000 tonnes of glass into higher value markets by 2006.

Brick industry

This week, the government-funded organisation also revealed new research suggesting recycled glass could be used in the brick-making industry. WRAP sees the brick industry as a major potential use for recycled glass.

A two-year project carried out by CERAM Building Technology found that by using 5% of powdered glass as a fluxing agent in clay bricks, the energy needed in the manufacturing process is reduced by 20%.

As well as providing a use for recycled glass, the energy-saving nature of its use as a fluxing agent would also cut carbon dioxide emissions from brick manufacturers. This would help manufacturers meet their Climate Change Levy obligations and could also be important when the new emissions trading scheme comes into effect in January next year.

Dr Andrew Smith of CERAM said that the use of recycled glass in bricks also enhances the performance of the bricks themselves. He said: “The addition of glass powder was shown to enhance the performance characteristics of certain products, especially in terms of strength and durability.”

The use of 5% recycled glass a year in the production of bricks would also save clay reserves to the tune of 350,000 tonnes each year, WRAP said.

Tender

Trials using the recycled glass have been carried out with Blockeys Brick Ltd, Hanson Building Products Ltd, Ibstock Brick Ltd and York Handmade Brick Co Ltd. WRAP has now launched a tender process to fund full scale operational trials involving the use of recycled glass in selected end market applications including in the brick industry.

David Roberts, general manager at Blockeys Brick, said: “With the type of clay we use, the results of the project have been of sufficient interest for us to consider further larger scale trials.”

Subscribe for free