Yorkshire-based Rockware Glass said that the machinery, being used at collector Berryman's sorting plant, produces much purer clear glass than previously obtained. This means that a much higher proportion of recycled glass can be used to make containers (bottles and jars) than before.

Risk

Malcolm Vernon, director of logistics at Rockware, said: “At present, when we reach between 50% and 60% recycled content in clear glass, we start to see a greenish tinge appear. If this is unchecked, we risk incurring customer complaints.”

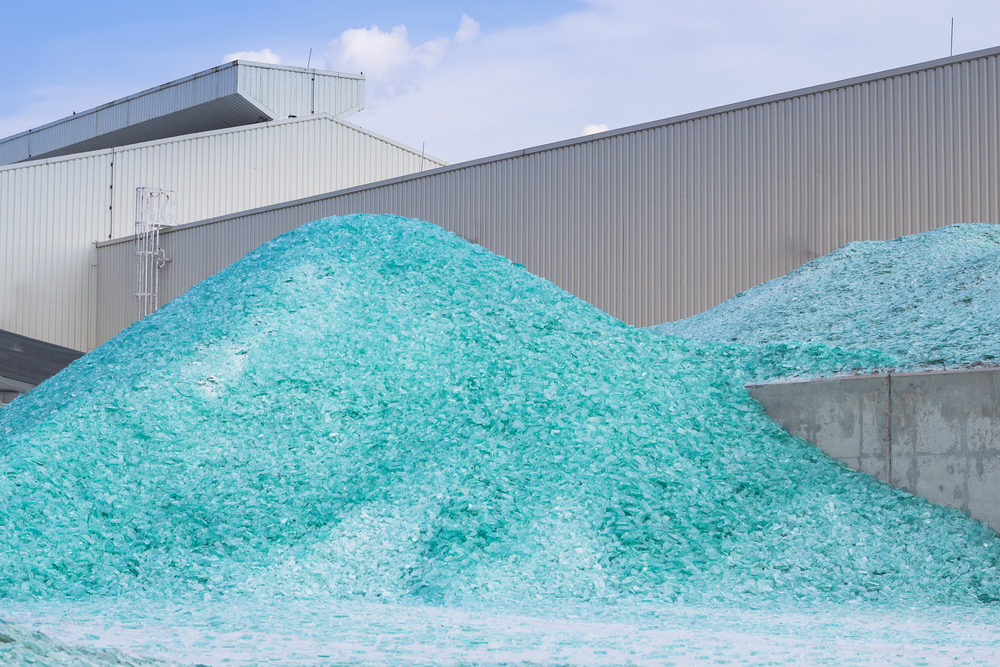

The amount of recycled cullet currently used to make clear containers at Rockware is around 25-30%. But green containers contain up to 93% recycled green cullet. This is due to both higher availability of green cullet and the fact that impurities are less noticeable in green bottles.

Rockware marketing manager Andy Hartley said that because the new machinery has reduced the amount of coloured glass in the clear stream from 5% to just 0.5%, about 93% clear cullet could now be used to make clear containers. This could mean an increase of around one million tonnes in clear cullet.

“This breaks a traditional barrier for us in making clear glass,” he said. “The amount of clear glass made in the UK each year is 1.2 million tonnes. The amount of green glass made is 300,000 tonnes, so this is a much more significant development than quality improvements last year that allowed us to use a lot more green.”

Enhancement, not separation

Mr Hartley emphasised that the new technology was designed to refine the colour of glass that was already sorted into different colour streams – not to separate mixed glass. “This is the biggest colour enhancement facility in the UK,” he said. “But we are not talking about colour separation – the plant takes glass that has already been colour separated by hand or at a MRF, not mixed glass.”

And he advocated kerbside collections as opposed to bottle banks. “Fifty percent of the glass collected from bottle banks is green, but 50% of the glass collected from the kerbside is clear,” he said. ” Clear has the highest value because there's so little of it available and there's a big market in the UK, so imagine the difference it would make for us if the glass supplied changes from 50% green to 50% clear.”

Although kerbside was more expensive, he said, imminent increases in Landfill Tax could make it more appealing, and the fact that bottles were not broken meant they could be separated more easily and cheaply than by a reprocessor.

“The positive thing about kerbside is that not only do you double the glass collected in any given area, but of that glass, 50% is clear and when it's separated on the vehicle or at a MRF, the quality is excellent,” Mr Hartley said.

Subscribe for free