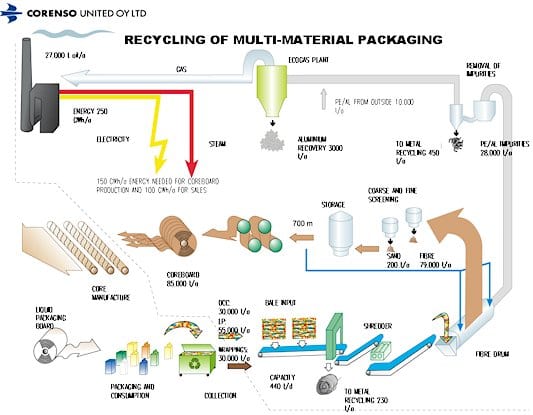

Finland is justly proud of its development at Varkaus which not only recycles the paper content of the carton but also uses the plastic liner for energy recovery and collects the aluminium coating for further refining and re-use. The recovered fibres are used for the production of cores which come in a remarkably wide range of sizes, from cores for large paper drums, through to centre cores used for small-scale packaging jobs.

Finland is not normally famous for its recycling work as its main material role is the production of virgin fibre. But, the country is making considerable strides to develop recycling: it already recycles some 70% of paper generated inside Finland; its paper industry is investing in recycling mills outside of the country; and it has the carton recycling plant at Varkaus.

Owned by paper giants Stora Enso and UPM-Kymmene, Corenso believes the Varkaus mill to be the only one in the world where 100% of liquid packaging components are recycled.

Its remarkable position in the centre of the town of Varkas reflects how the town has developed around the mill. The plant itself is seeing considerable investment at present with a new thermo-mechanical line being built with the closure of groundwood pulp line. The mill consumes a massive 2.4 million cubic metres of wood a year and, as well as core making, it produces fine papers and publication papers including newsprint. Investment at the site in the current financial year will total 80-90 million Euros.

The carton recycling plant has been built at the side of the mill alongside one of the old mill buildings which contains the pioneering Ecogas plant that makes use of the 30% non fibre content of a drinks carton – plastic goes to energy use and aluminium for use by the metal industry.

Most of the imported cartons for recycling come from Germany. This is a form of reciprocal agreement – Finland exports the cartons and Germany through the DSD system can afford to return the material for recycling. Use is made of rail transport with Varkaus having good access to European freight rail routes – the plant processes the equivalent of 12 railway wagons of compressed bales of collected material every day.

The amount paid by Germany for processing the material has not been revealed although it is thought to be in the order of several hundred Euros per tonne. This gate fee is nor surprising considering that the raw material has a low value and the Ecogas plant alone cost 20 million Euros to build while the total cost of the carton recycling facility overall is estimated at 45 million Euros.

Corenso recycling manager Jukka Auvinen explains that the plant started up at the beginning of 2001. To produce the coreboard production of 85,000 tonnes a year about 52,000 tonnes of recycled fibre from the cartons is used as well as “We take in about 85,000 tonnes of liquid packaging cartons a year. About 50,000 tonnes comes from Germany. The rest comes from Finland with a few thousand tonnes from Holland.”

The plant does not at present take any material from the UK but Mr Auvinen said this might be possible in the future and some talks about this were planned.”

For coreboard production at Varkaus of about 85,000 tonnes a year about two thirds of the fibre comes from the cartons with one third coming from used cardboard and mixed waste paper.

The energy plant, which has been designed by Foster Wheeler, generates about 25 GW of energy a year, enough to heat a Finnish town of 40,000 people throughout the long cold Nordic winter. Aluminium recovery from the process stands at about 3,000 tonnes a year, although users are still being identified. While the recovered material contains aluminium there is also an element of “coal” like particles and so the aluminium will need an element of further processing although Corenso is confident that customers will be announced shortly for the material.

Now, the message from Corenso is that more plants of this type are needed throughout the world. “To recycle just 50% of the world's used packaging which contains aluminium foil would enable hundreds of Ecogas plants to be built, replacing at least one 1,000 MW nuclear plant.”

Subscribe for free