A jointly constructed by Midland Glass and Associated British Ports, the facility benefited from an 800,000 Freight Facilities Grant from the Department of Transport.

This location allows glass to be directly transferred to ships to be taken by water to other ports in the UK such as in Humberside and Scotland. ABP claim it will take almost 2,000 heavy goods vehicle movements off the roads every year.

Environment minister Michael Meacher opening the new Midland Glass plant at Southampton yesterday |

The new dockside plant is expected to process around 24,000 tonnes of glass a year from the 10-year contract Midland Glass has had with Hampshire's Project Integra partnership since 2001. Glass will also come from authorities in Buckinghamshire.

Speaking to assembled members of Project Integra while opening the facility, the minister said: “This is a very good, pioneering technology allowing superior glass sorting by our private industry, which will benefit both sides – local authorities and private partners. It will raise household recycling rates both in Hampshire and Buckinghamshire.”

He continued: “Southampton has a high reputation for being innovative – it has the highest use of rail for freight than any other city, and now it is collecting glass from Hampshire and Buckinghamshire and barging it all the way up to Scotland – highly innovative.”

The first shipment of glass material from the new plant set sail from the plant on March 12 2003, on the MV Sea Kestrel bound for the Port of Goole on the Humber Estuary. The ship transported the equivalent of 45 lorry loads of crushed glass.

Technology

The Southampton plant has state-of-the-art colour sorting equipment using American MSS Colorsort technology.

The system works by examining pieces of cullet the size of two pence pieces with lasers while it is in freefall. A computer takes 25 milliseconds to decide whether to accept the glass or reject it, and a high pressure jet of air then fires on pieces that are unacceptable for the current batch.

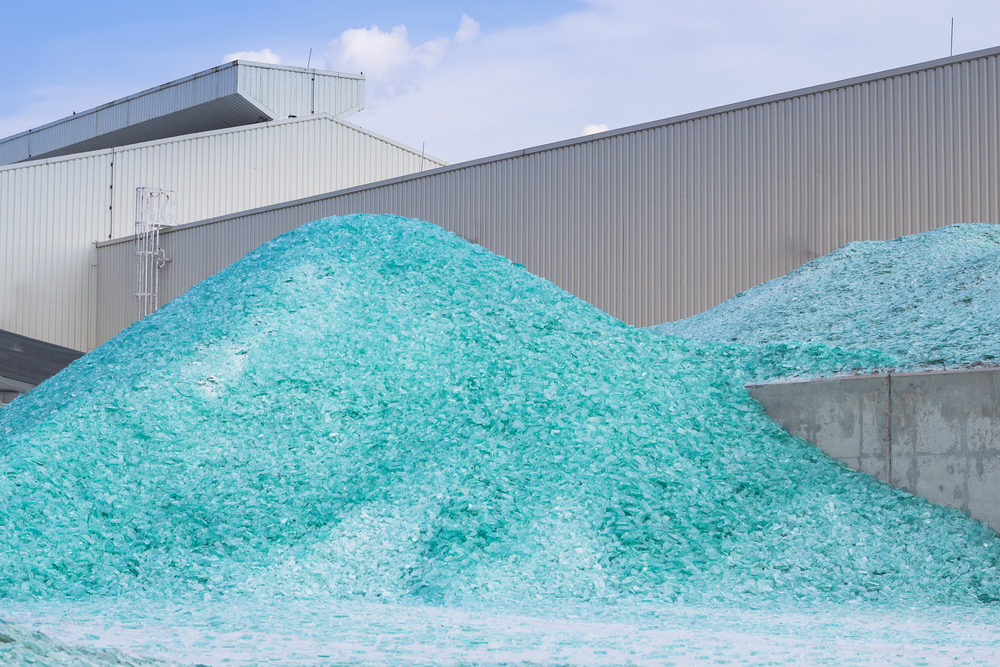

The new plant's location allows it to transfer crushed glass direct to ships in the port |

Eric Gent, operations director at Midland Glass explained that the facility has two of these optical sorting machines working nine hours a day, each able to process around 20 tonnes of glass each hour. A third machine acts as a back-up to cut down on wastage, as a small proportion of acceptable glass comes away with the unacceptable material.

Mr Gent said: “Clear glass always goes to the container industry, but green and lower grade material tends to go to aggregates.”

Continued on page 2

Subscribe for free