Electrical Recycling's plant at Hessay, York, uses an 80% automated process to separate the two types of glass, panel glass and funnel glass. The facility is currently processing 24 tonnes, or 2,000 screens, each week of CRT glass, mostly from CA sites but also some from small contracts.

Electrical Recycling is a partnership between waste management company Yorwaste and electrical and electronic equipment repair firm DBS. The project is on a Yorwaste site at Hessay which has a hazardous waste management licence. The companies are researching options for the handling of difficult items that will come under the European Waste Electrical and Electronic Equipment (WEEE) Directive.

The CRT research work has received support from Yorventure, Yorwaste's environmental body. The project costs are currently running at about 180 per tonne or 3 per TV, but these costs many double in the future as the logistics of the project are currently subsidised.

Hazardous

Yorwaste's recycling manager, John Miller said that Yorwaste wants to be able to provide recycling services for WEEE for local authorities. “We are very much in partnership with ERC to handle hazardous waste from the WEEE Directive. We are trying to put together a solution ahead of the game.”

Due to be implemented into UK law in August next year, the WEEE Directive stipulates recovery and recycling targets for 10 different categories of WEEE to be met by the end of 2006. These include targets of 75% recovery with 65% recycling for the two categories that cover TVs and computer monitors, or CRTs.

Don Smith, director of Electrical Recycling Company, warned: “Everybody says we are already hitting the collection target of 4kg per head. But the Directive sets recycling rates by category for all collected WEEE which means all TVs and monitors taken to CA sites fall into that category.”

As it has been estimated that more than 100,000 units are being disposed of each week in the UK, CRTs pose one of the biggest challenges under the Directive. They contain two types of glass, which are difficult to separate and difficult to find markets for. Additionally, the lead and barium content of the CRT glass means any company handling old television sets or computers will have to obtain a hazardous waste management licence from the Environment Agency.

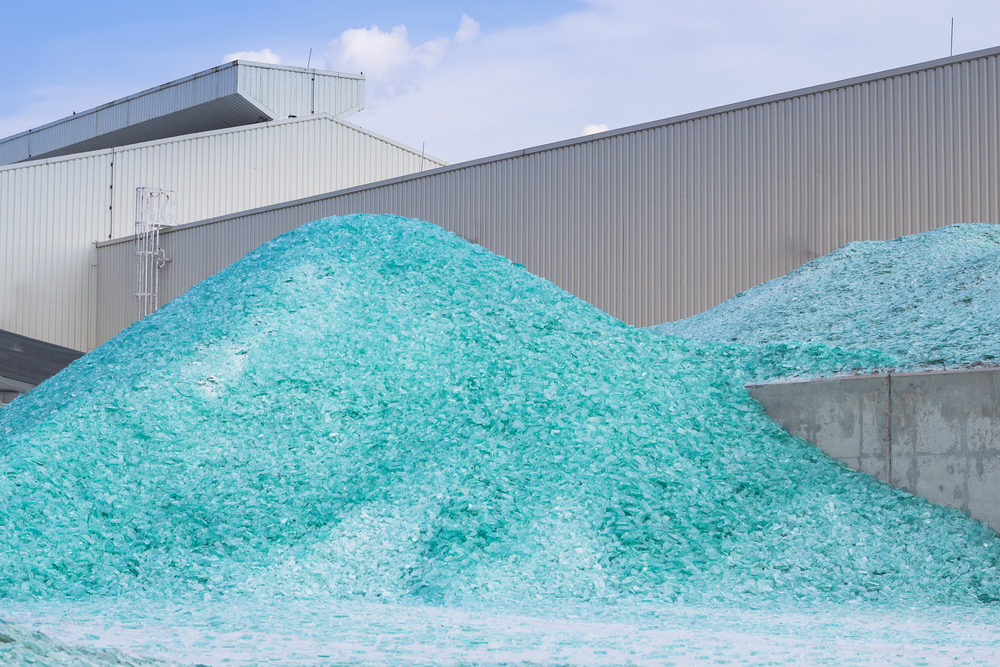

The Electrical Recycling research plant takes both CRTs by themselves and as part of whole TV sets or monitors, whose plastic is currently being sent to other research projects looking into uses for plastics from WEEE. In the automated plant the CRT glass is divided using a cutting system.

Markets

Mr Smith said that the system recovers 100% of the CRT glass and because it separates the two types of glass, unlike shredders, it opens up more markets for the materials. The glass is currently being shipped to the continent for use in the manufacturing of CRTs.

Mr Smith said: “The primary use of the glass is going back into CRTs in a closed loop manufacture process. We are working with research body CERAM about using the glass as flex within smelting and building and we are also working with WRAP to use it in one of their processes.”

Subscribe for free