The maker of the Silipaktor glass crusher, which has just celebrated its first birthday, said that crushing glass before it is transported for sorting reduced noise pollution, cut the number of collections needed and saved money.

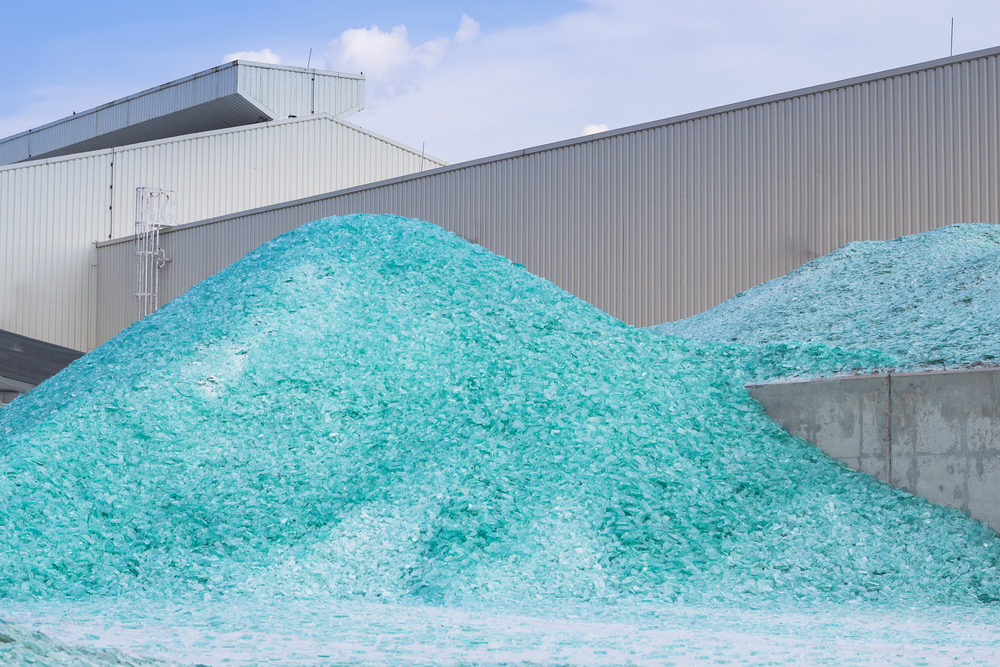

The Silipaktor glass crusher |

The first Silipaktor glass crushers were installed at London hotels in May 2002. Twelve months on, Glass Compaction Services said: “The benefits to waste generators, waste management companies and the general environment are apparent.”

“In the past, it has not been possible to collect waste glass in relatively significant quantities (over 250kg) from individual premises,” a spokesman for the company said. “But Silipaktor crushes waste glass into unique steel 240 litre wheeled bins capable of holding nearly 300kg of cullet and which are also easily lifted and emptied by standard hydraulic equipment.” Special vehicles or adaptations are not needed for this process, it added.

Savings

In six days, one vehicle that normally collects 35 tonnes could collect up to 84 tonnes of crushed glass, leading to large potential savings in operating costs, the company said.

The equipment is also intended to reduce transport costs. “Assume a lorry has a maximum payload of ten tonnes. If it picks up four 660 litre bins of uncrushed waste glass containers at each stop, it would have to visit 18 premises to reach payload. If, on the other hand, it picks up four 240 litre Silipaktor bins of crushed waste glass at each stop, it would have to visit only nine premises to reach payload,” the firm said.

Managing director Andrew Mackenzie said: “It would appear that the sooner all stakeholders adopt a policy of 'c;rush at source' in the case of waste glass, the quicker economies of scale can be brought to bear upon the issues of collections.”

Andy Dawe, the materials sector manager for glass at the Waste and Resources Action Programme, said: “Innovations of this nature are fundamental in helping to achieve increased recycling rates.”

Subscribe for free