The West Yorkshire-based collector acquired RMG, which collects mixed glass from pubs, clubs and restaurants, from Valpak in April 2003. But Berryman's existing sorting plant in Knottingley is only set up to refine the quality of glass that has been collected in separate colours.

Solved

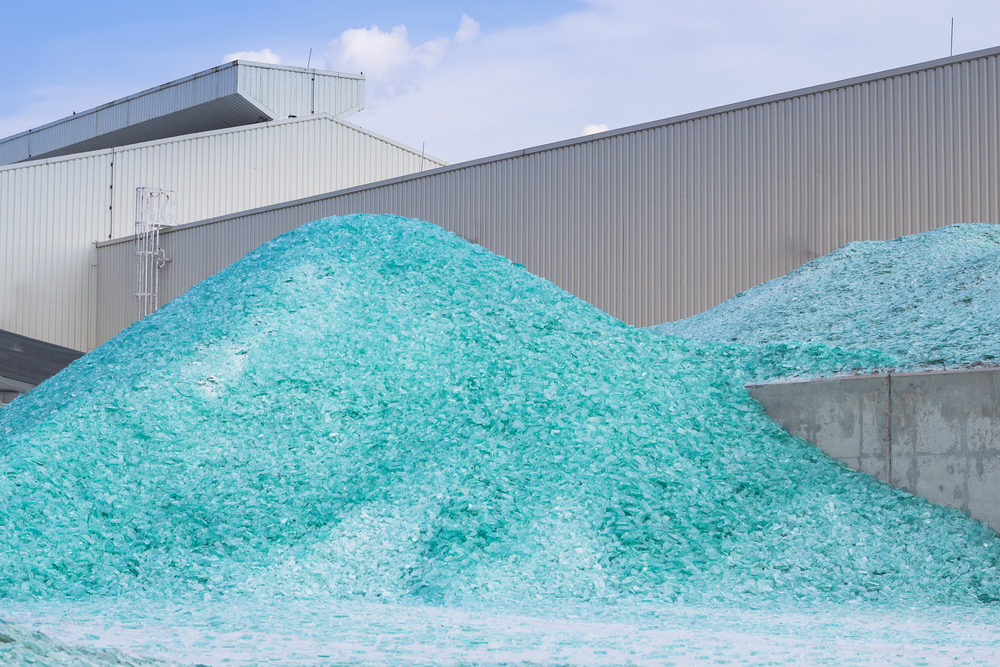

Now Berryman says it has solved the problem of extracting white and amber cullet – the most valuable colours – from mixed glass by investing 2.5 million in the UK's first large-scale colour separation plant.

The new sorting plant is due to start operating in December 2003. Spokesman Nigel Keenlyside said machinery made by German firm S&S; will use X-rays to remove white and amber glass from mixed batches. The remaining glass will be used for green.

The plant will process at least 60,000 tonnes of glass a year – the amount currently being collected under the RMG scheme. This will make it the largest colour separating facility in the UK, Mr Keenlyside said.

“Colour separation is different to colour improvement, which is something we carry out at our other plant on glass that has been collected in separate colours,” he explained. But he said there was no percentage figure yet on how pure the resulting glass colours from the separation plant would be.

Knottingley

Berryman has also just opened a 2 million “auxiliary glass recycling plant” to complement its existing plant in Knottingley, West Yorkshire. The new extension will re-process the 20% of cullet that is rejected from the main plant after being sorted a first time – about 40,000 tonnes of glass a year.

The new plant will put the rejected glass through a series of sophisticated detection processes to enhance colour and remove ceramic, pyro-ceramic and metal contaminants. The company estimates that once glass has gone through this process, just 1-2% of the original glass collected – about 3,000 of the 200,000 tonnes collected each year – will still be unusable.

Manager of the Knottingley plant Jamie Brown said: “We are now supplying the best quality ever produced to our customer and have reduced the “unusable” cullet to a practically negligible level.”

Subscribe for free