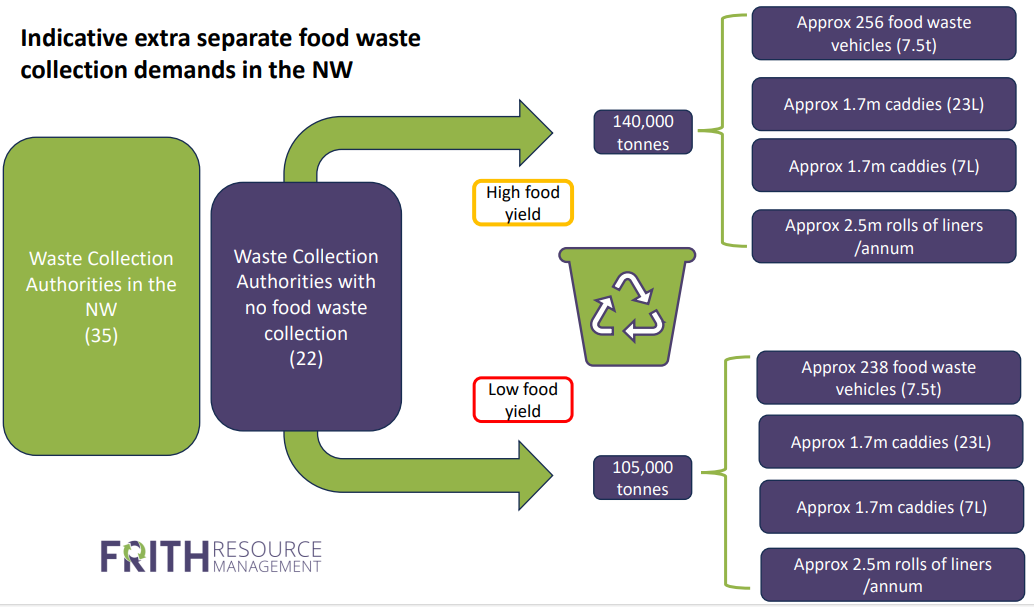

SPECIAL REPORT: What might the costs be to a region for introducing food waste collections by 2026? This is a question we decided to look at as a case study for the North West region of England, firstly by identifying the Waste Collection Authorities that have not yet implemented food waste collections and then by projecting the tonnages which could be derived.

In the NW around two thirds of WCAs have not yet implemented a food waste collection. The focus of this article is on the capital cost of collection of this extra household food waste, but there is also some commentary on other aspects. Here are the results:

This outline modelling applies industry assumptions around anticipated yield of separate collection of food waste from different types of authority and their respective population. We included a lower and higher yield using the WRAP ready reckoner (the low and mid points respectively) – based on experience.

It would be anticipated that some form of residual waste restriction would need to be in place to achieve the higher yields shown here. No non household municipal food waste is included here, although that will create major capacity and infrastructure challenges in its own right.

We assumed a typical round size for the lower and high participation from householders (for the low and high yield respectively) to derive an indication of the number of vehicles needed. We costed for separate 7.5t dedicated food waste vehicles across the board (although other collection options are available). No comingling of organics is assumed, and we assumed liners provided to each household for the separate collection.

Costs

The total costs for the provision of the containers and vehicles are c. £36m in the low yield scenario and c.£38m in the high yield scenario. This is based on individual councils purchasing and in the current market. If the councils in the North West procured collectively it would be envisaged that around £3.5m – £4m could be saved from this outlay (this is based on experience and economies of scale e.g. as recorded through procurement frameworks). It should be noted that some of these costs will re-occur each year (c. £2.5m on liners) and other capital costs as a result of replacement (e.g. containers and at the end of a vehicle’s life).

We have not included the operating costs (labour, fuel, standing & running vehicle costs, depots) here, although these could be approximated, and around 500 staff would be needed, assuming a driver + 1 combination. We have costed for diesel fueled vehicles, but note that electric variations are available and would currently add 35-50% on the capital cost for 7.5t vehicles.

There are of course significant other factors that would need to be considered ranging from: comms for householders; sufficient depot space for parking / re-fueling 240 – 260 food waste vehicles; bulking / transfer arrangements + associated permits, and; the small matter of food waste treatment!

The additional food waste tonnages from councils implementing separate collections in the NW region could provide the entire feedstock for 2 to 3 dedicated commercial anaerobic digestion plant or a larger number of smaller (e.g. on farm) AD systems. Sufficient outlets for the digestate also needs to be considered in terms of markets for the outputs from the processes.

The challenge, given the 2025 (businesses) and 2026 (households) Simpler Recycling dates is significant, and the costs herein are likely to be markedly lower than that presented by the market when demand peaks. This is of course only one of the regions in England facing this concurrent issue, in combination for England as a whole, it represents a substantial overhaul of infrastructure and systems and a huge set of procurement / equipment supply challenges. It is however, a change that will improve carbon performance and add an element of energy security to the UK. In terms of costs and deliverability, as ever, planning ahead and some coordination will be key.

Frith Resource Management provide technical modelling, market assessments and procurement support. For more information see www.frithrm.com, call 01746 552423 or email paul@frithrm.com

Subscribe for free