The facility in York which makes over a billion Kit Kats and 183 million Aeros each year has increased its recycling rate to 93% with the help of local waste and recycling contractor Yorwaste. The remaining 7% of waste is sent to an energy-from-waste facility identified by Yorwaste, which isaround 60 miles fromYork.

Key to the success of the partnership has been the appointment of more than thirty Nestl recycling champions who oversee the different kinds of waste generated at the York site.

Nestl has a target, within its sustainability programme, for all 14 of its factories in the UK and Ireland to achieve zero total waste by 2015. Girvan on the west coast of Scotland – where chocolate crumb is manufactured – and Dalston in Cumbria where Nescafe Cappuccino is made – achieved the goal in 2010.

Yorwaste

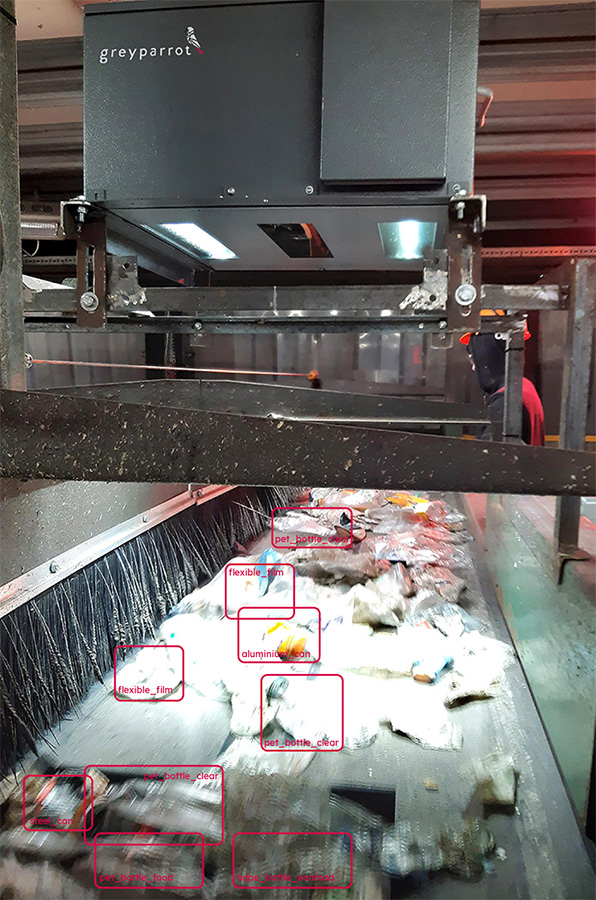

Yorwaste first began working with Nestl in 2002 and staff from the company work permanently at the York factory overseeing different types of waste generated. This includes paper, plastic, cans, glass, packaging, hazardous waste, confidential waste and electrical waste.

Much material is taken to Yorwastes nearby materials recycling facility at Hessay or its Resource Recovery Centre at Harewood Whin. Where Yorwaste does not handle the material directly, it acts as a broker to market the material.

Steve Grieve, managing director of Yorwaste, said: We are delighted to have been able to work with Nestle to provide a total waste management solution that now officially means that not one single piece of waste produced at the York site is sent to landfill.

John Billett, from Nestl, said: We would not have been able to achieve zero waste to landfill without the continuing support of Yorwaste over the years. They have become embedded at Nestle York and are not seen as contractors, but as valued members of the team.

Progress

In addition to reducing waste, Nestl said it had made significant progress in reducing packaging used in Easter Eggs, Christmas selection boxes and catering Nescaf stick packs and sachets.

Paul Grimwood, chairman and chief executive of Nestl UK & Ireland said: Although there is still much to do in our sustainability journey I am very proud of what our employees have achieved in such a short time. At Nestl we are committed to manufacturing and doing business in a way that protects the planet and its resources for future generations and helps our local communities thrive. Making such progress in reducing the amount of waste our factories send to landfill, how much water we use and packaging we produce are significant steps.

Subscribe for free