The furnace, which has been installed at a cost of £2 million, has been developed by Manchester-based CRT recycling specialists Nulife Glass, and is capable of processing around 10 tonnes of television glass per day.

Crushed leaded television glass is fed into the furnace and heated to over 1000 degrees centigrade using powerful electrodes, whereupon a chemical compound is added which causes the lead to sink, and the glass rises to the top of the mix.

Extracted lead can then be sold on for manufacturing, with the company looking at a number of outlets for the pure glass product.

Leaded CRT screens are composed of around 20% lead, with the average set containing around 1kg of the material. Installation of the furnace began in July, with the first glass going in earlier this month.

Innovation

Justin Greenaway, contracts manager, SWEEEP Kuusakoski, said: “Innovation in industry is part of the UKs heritage and this is still very much the case with the opening of our SWEEEP Kuusakoski waste TV glass recycling furnace. Nulife glass invented the process to extract 1kg of lead from each waste TV recycled and the first industrial application of this technology is now fully operational.

“Waste TV glass is a global issue and the UK recycling industry is at the forefront of providing the solution. The drive for greater resource security is an opportunity for sustainable economic growth and it is pleasing to be part of this.”

Due to the hazardous nature of lead, outlets for recycled leaded CRT glass have traditionally only included use in aggregates, in construction material or in the production of new CRT glass. These methods mean that the valuable lead component can no longer be extracted.

And, with the number of facilities producing new CRTs worldwide dwindling, demand for the material is limited. But, SWEEEP believes that the installation of the furnace will provide a vital new outlet for leaded glass.

The technology has been developed over 10 years by Nulife Glass founder Simon Greer. Mr Greer used a demonstration furnace in Manchester to prove the effectiveness of the technology.

Nulife Glass is also looking to export the technology overseas, and has had interest from the US and Far East.

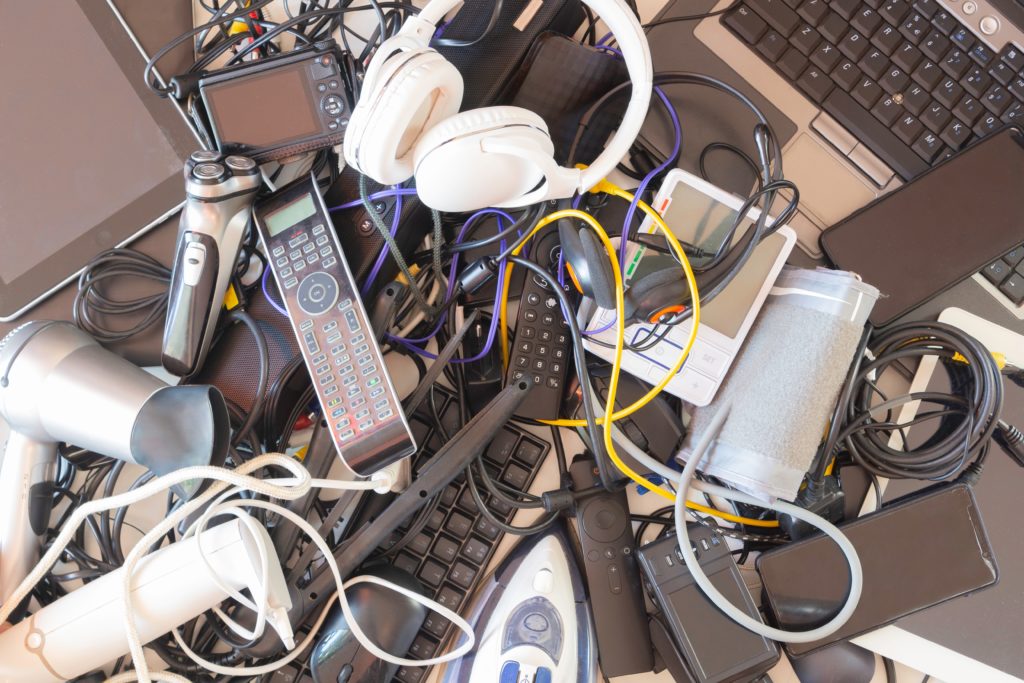

As well as CRTs, Kent-based SWEEEPs 100,000 tonne capacity facility sorts and processes small mixed WEEE. The site is currently being expanded to enable the company to store additional CRTs for recycling.

Subscribe for free