Reworked, based in North Yorkshire, specialises in “harder to handle materials” classed as residues, when other recycling has taken place and the more valuable or usable elements removed.

The company also repurposes the materials into new items, such as storage containers that will be used in Boots stores.

Reworked is also sister company and the plastics recycling arm of composting company Maltings Organics. The partnership is managed by Steven Carrie, who is the director at both Maltings and Reworked.

Boots

It worked in partnership with the retailer Boots to run a recycling scheme, launched in September 2020, to provide a way for customers to hand over empty health, beauty and wellness products for recycling. So far, over one tonne of plastic has been recycled.

The products deposited for the scheme are collected by Reworked and sent for recycling at its facility in South Milford, Yorkshire.

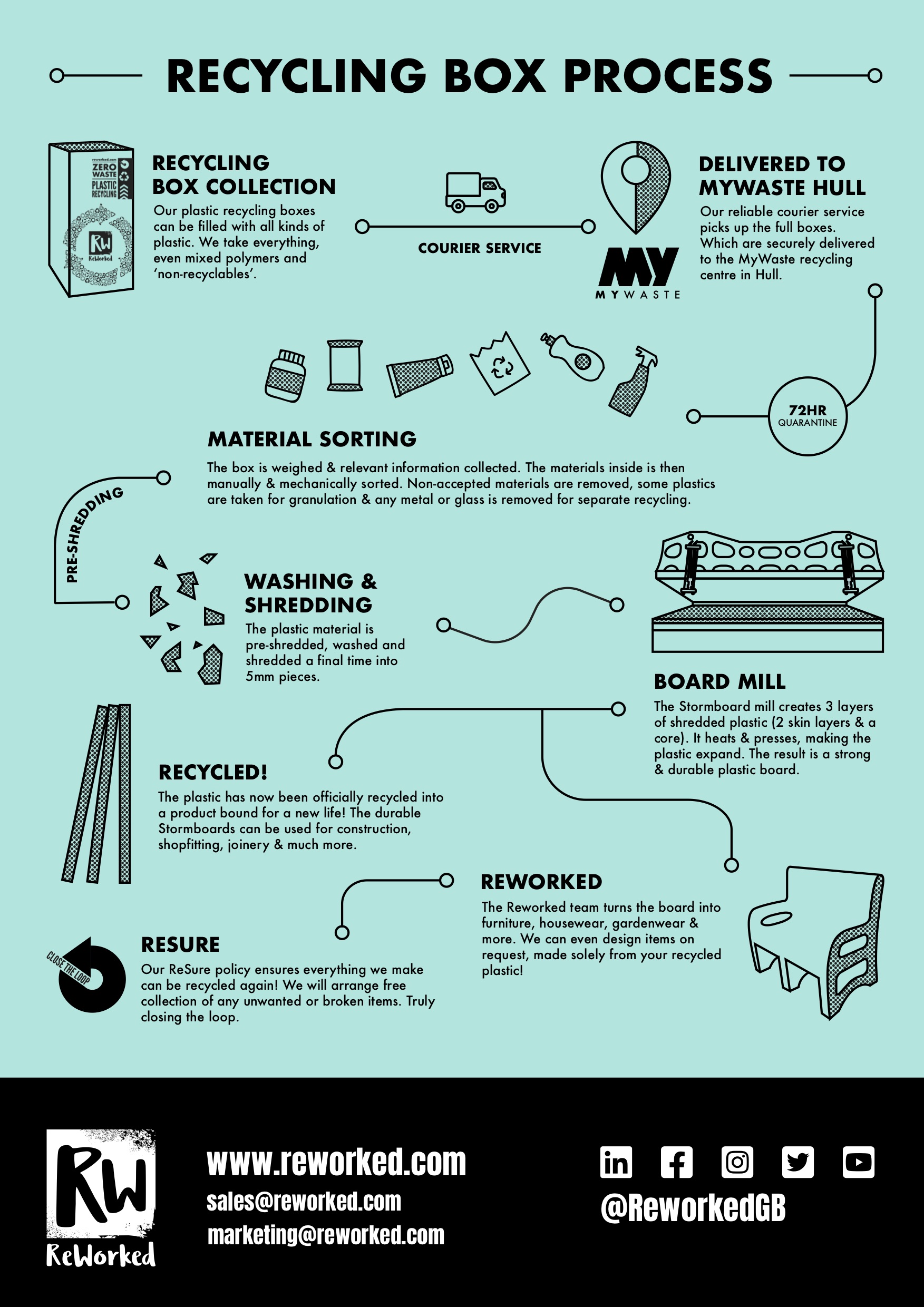

Process

Reworked told letsrecycle.com that most of the products taken through the Boots/No7 scheme would be considered “non-recyclable” using traditional recycling methods, because of mixed polymers and metal components.

Because of Reworked’s “innovative technologies and methods”, the business explained that it is able to recycle all polymers together, shredding and mixing them to a “specific recipe for consistency” then using its board mill, creates 100% recycled plastic sheets.

To recycle the products, the company firstly sort them by hand, at which stage anything containing metal is taken to be separated. Remaining materials are shredded all together, regardless of the plastic-type.

Mill

Products are recycled using the company’s Stormboard “making mill”, which is used specifically to recycle everything the products received from the Boots take back scheme. The mill creates three layers of shredded plastic (two skin layers and a core), and then heats and presses, making the plastic expand resulting in “a strong and durable plastic board”.

And, there is a series of washing and shredding stages to ensure that plastics covered in residues, which is common with make-up and health packaging, can be accepted.

Make-up products such as lipsticks and compacts tend to be the hardest products for Reworked to recycle due to their mixed polymers, which contain glass or metal components. Through hand sorting and various mechanical processes, Reworked shred the material and use it to create boards.

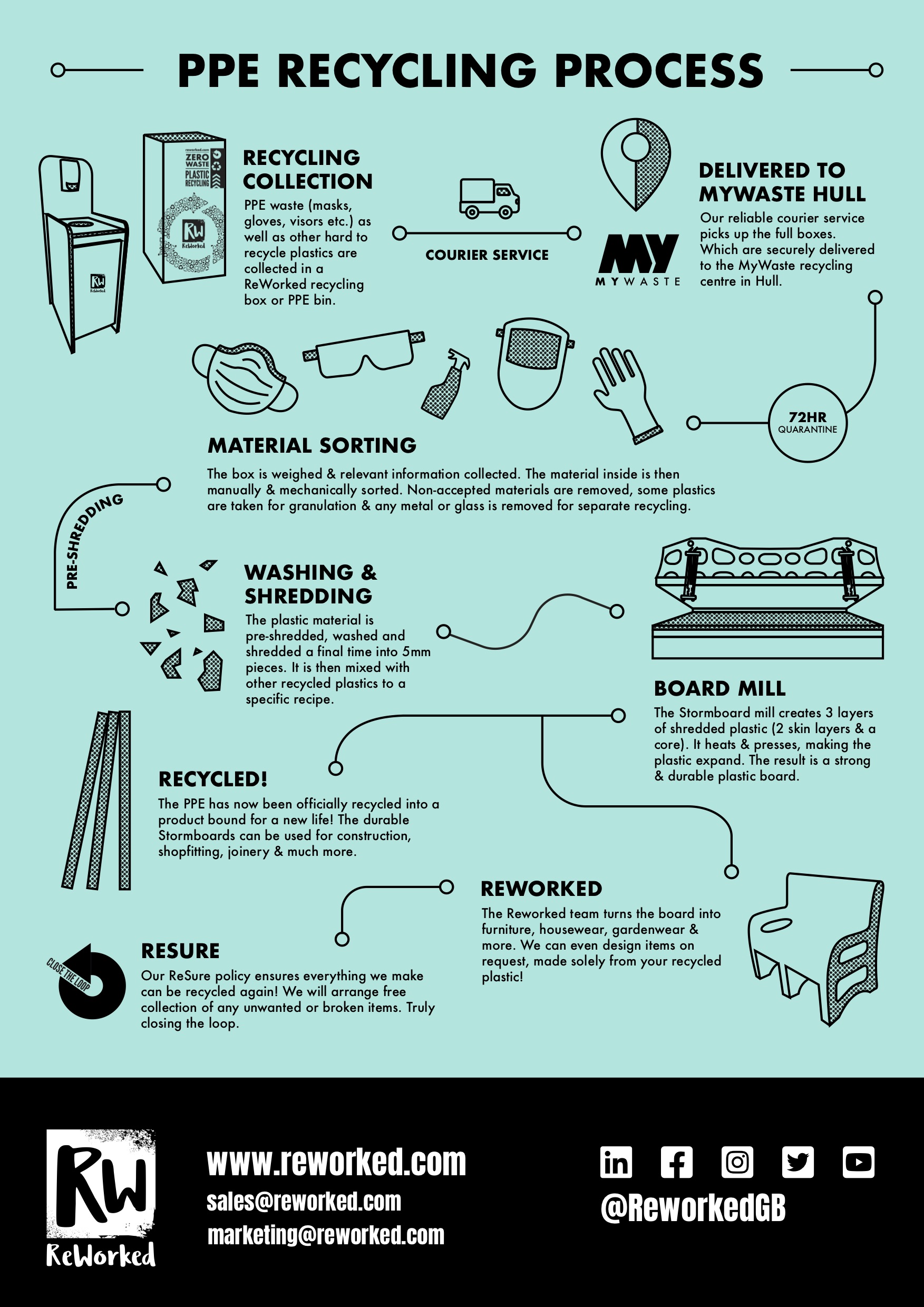

PPE

Reworked explained that despite the “lack of willingness” by many people, it is possible to fully recycle personal protective equipment (PPE). To do this, businesses can take part in the company’s “Reclaim the Mask” scheme, which entails using a recycling box for PPE that is then collected for recycling.

Explaining the process, the company said that there are two potential methods to recycle PPE, which includes either separating out the different polymer types and any PPE that is made of a single plastic to be granulated, or shredding any mixed plastic masks or PPE to make plastic boards.

To recycle the products, Reworked ensure that all recycling boxes are fitted with a liner and lid, so that the box and its contents can be secured safely.

Upon arrival at ReWorked HQ the boxes are quarantined for a minimum of 72 hours to prevent any potential virus spread. Metal strips found within some disposable face masks are removed and recycled on site separately from the other materials.

Sorting

During this initial sorting, any glass and metal parts for recycling are removed and then plastics are put through a pre-shredding system to open the structure up. ReWorked described this process as “vital” to remove any residues.

Residues are also removed through high-pressure washing, and are then dealt with at the company’s organics facility. Once clean, the materials are shredded again into 5mm pieces. This is blended with other plastics to make up the core of our boards.

The plastic mix is taken to the board mill to be pressed into 8×4 sheets. The Stormboard press lays two ‘outer coatings’ and a core, before using heat to fuse into a durable sheet.

Subscribe for free