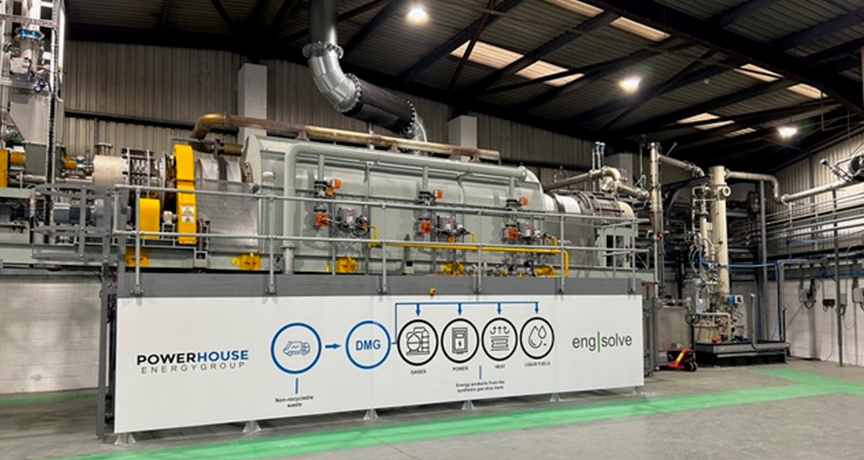

The unit was demonstrated to 50 investors at a private showing at the Technology Centre at the company’s headquarters in Bridgend in Wales.

The technology, which can also be used for carbon capture, is intended to be turned into a commercial plant down the line.

The current FTU is a scaled version of DMG Technology and is capable of processing 2.5. tonnes per day. A typical commercial unit will process 35 tonnes per day.

DMG Technology uses pyrolysis to break down waste into its chemical components in a rotary kiln. The technology has been in development by the company for nearly a decade.

CEO of Powerhouse Energy Group, Paul Emmitt, said: “Powerhouse is aware of the problems that have dogged using pyrolysis and gasification on waste, and hence, to date, we have focused our efforts on research and development, culminating in this FTU.

“The purpose of the FTU is to mimic a full-scale plant, but at a scale where we can test materials and change process parameters without incurring wholesale changes, which on an operating commercial plant can prove to be very costly.”

Powerhouse demonstrator unit

The group has been running a small “demonstrator unit” at the at the University of Chester campus in Cheshire ahead of developing the FTU.

The unit allowed it to study the pyrolysis and gasification processes of various waste materials and develop patents that are now filed and in force.

Emmitt added: “The demonstrator was a laboratory system. It was necessary for us to develop something that looks like the real thing so that potential clients could take a look and ‘kick the tyres’ – hence the FTU.”

Subscribe for free