William Tracey’s buys reconditioned RCVs

Waste management firm William Tracey Group has bought two fully reconditioned refuse collection vehicles in order to expand its fleet.

The Mercedes Econic RCVs are fitted with Heli compaction bodies and Zoeller trade lifts. They have also been fitted with onboard computer technology, suppied by AMCS Group.

William Tracey Group’s managing director, Non Hazardous Waste Division, Robin Stevenson, said: “The increase in availability of reconditioned vehicles means that they are now a realistic option when we need to expand our fleet. Reusing vehicles enables us to implement the waste hierarchy in to our own business and to genuinely practice what we preach.

“The reconditioning and original build quality means that they present a practical, sustainable and cost-effective alternative with all the technological capability of a new vehicle.”

MID UK Recycling awards plant contract to TOMRA

Sensor sorting equipment provider TOMRA Sorting has been awarded a contract to upgrade MID UK Recycling’s commercial and industrial waste processing facility at Barkston Heath, Lincolnshire.

The TITECH autosort 4 will recover plastics, paper or remove metal from feedstock. The unit combines near infrared (NIR) and visual spectrometry sensors (VIS) and is capable of sorting to a resolution of 2.5mm.

The TOMRA-owned technology will replace existing equipment used in the sorting process, and enable the recovery of ‘3D’ plastics at the plant.

Steve Almond, UK sales at TOMRA Sorting, said: “The additional TITECH units will enable our customer to recover a new recyclate stream, 3D plastics strengthening their place within the market. In addition, TITECH technology will significantly reduce the amount of operational down time at the plant, providing a cost-effective upgrade.”

Jayplas takes delivery of Erema extruder

Plastics recycling firm Jayplas has announced that it has completed installation of a Erema 212 extrusion system at its plastics LDPE plastic film wash plant in Loughborough.

The LDPE granulate produced at the plant will then be used in Jayplas’ Worksop site.

The firm hopes that the new extruder from Austrian manufacturer Erema will help it to increase capacity at the plant and enhance the quality of the products it produces on site.

Mike Maxwell, the firm’s operations director, said: “The new kit is going to increase throughput for the plant and the overall extrusion capacity within the business. It will also increase the quality of what we are manufacturing.”

Yotta software helps reduce missed bins in Preston

Preston city council has adopted Yotta’s Mayrise Waste Management software to help reduce missed bins and improve street cleanliness in the area.

The Yotta software records an inventory of both household and trade waste bins as well as mapping and photos, enabling ‘swift and more effective’ responses to customer enquiries.

The software can also be integrated with third party IT systems, allowing for easy sharing of data and producing performance indicators across waste and recycling operations.

Duncan Coward, head of waste management at Preston city council, said: “Yotta software is embedded at the heart of operations across a range of the most high profile Council services. The improvements we have made, and continue to make, would not have been possible without it.”

“As a result of the introduction of Mayrise Waste Management software we have been able to reduce missed collection reports by over 70 per cent. This is in addition to numerous other service improvements, enabled through linkages to our website and direct access to data contained within the Mayrise system, including ordering of new bins, bulky waste collection requests and street cleansing issues.”

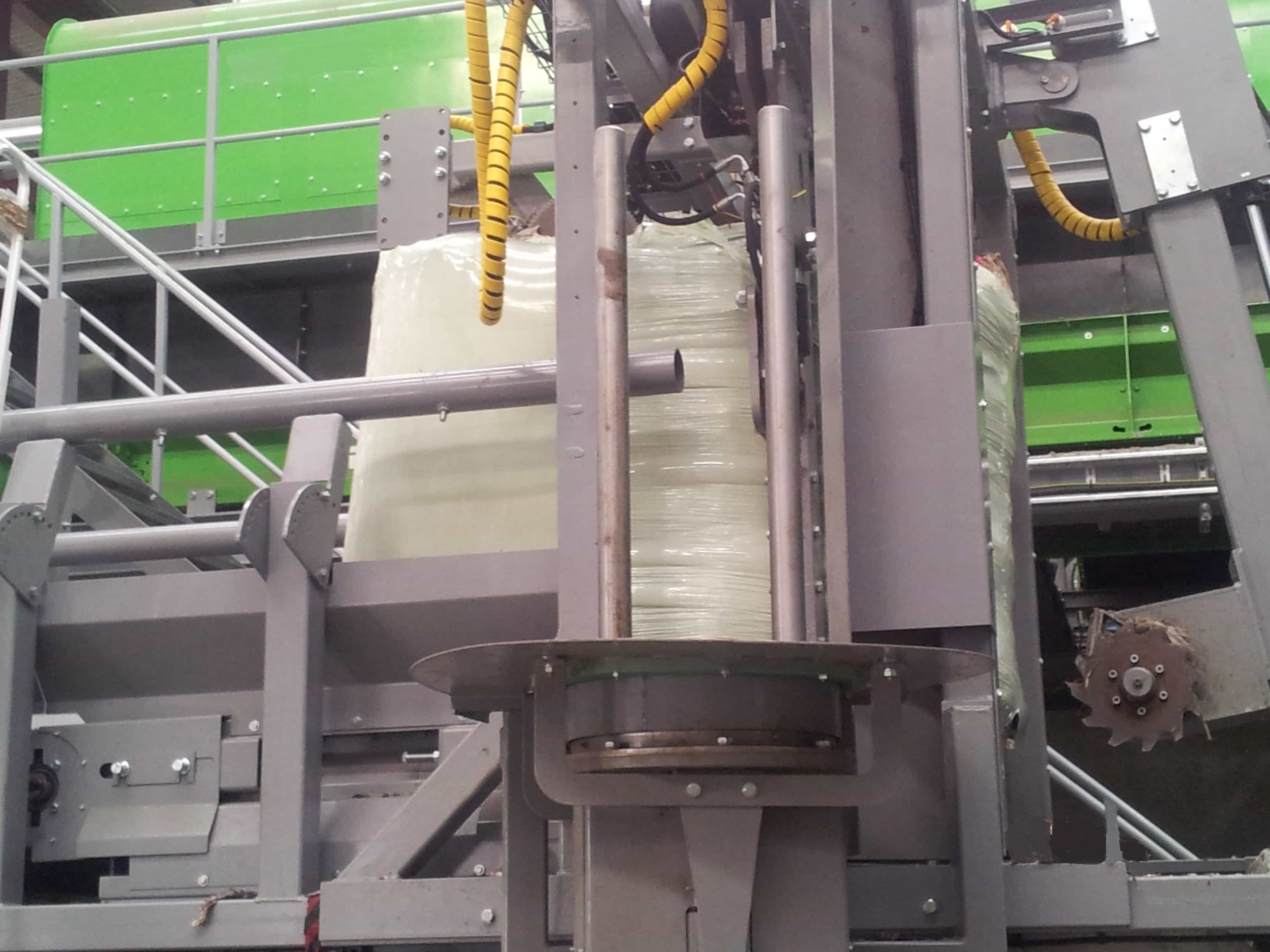

Cross Wrap announces delivery of bale opener

Bale wrapper manufacturer Cross Wrap has delivered a bale opener to Impetus Waste Management’s facility in Stockton on Tees.

The bale opener is used to automatically open RDF bales and separates the film and bale ties from the baled material. The machine has the capacity to unwrap 100 tons per hour.

It follows delivery of more than 50 to the UK, crosswrapping RDF, SRF bales to be exported. Cross Wrap has also delivered the equipment to energy-from-waste plants in Austria, Germany, Sweden, France and the Netherlands.

The firm also produces balers, which are suitable for all sizes and compatible with any square baler. The wrappers are fully automatic and have a capacity of up to 80 tons per hour.

Subscribe for free