“Accidental ignition of paper” has been revealed as the cause of the blaze (see letsrecycle.com story).

Now, the company is thought to be optimistic that it will be able to run one of its two winder machines which will allow for at least 50% production in the short term, while some of the complex machinery and equipment is repaired or replaced.

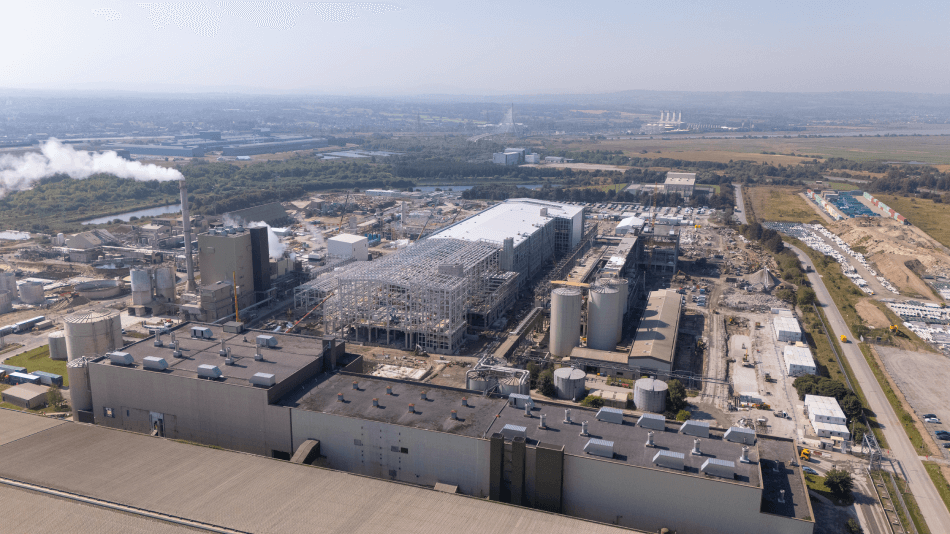

The King’s Lynn mill manufactures 450,000 tonnes of newsprint per year from recovered newspapers and magazines and supplies many of the UK’s regional and national newspaper publishers. It also produces a variety of other paper types for coldset, heatset and litho printing processes.

The UK’s Palm Paper is part of Germany’s privately-owned paper firm Papierfabrik Palm which is also a major producer of corrugated board. It owns a total of five mills with 28 paper machines and has recycling business in Germany and the UK. All of its products are made from recovered paper.

Newsprint

Dr Wolfgang Palm, chief executive of Papierfabrik Palm, today (24 October) assured letsrecycle.com that on the newsprint supply side, customers were being kept fully informed and that supplies of newsprint were fully available. However, he noted that at present no further official update was available.

The King’s Lynn site is an important user of used newspapers and magazines which it sources from across the UK. At present Palm is thought to be reducing its orders for incoming material with some merchants hoping that their deliveries will start again in November. The other UK mill user of used newspapers is UPM’s mill at Shotton in north Wales.

Reductions

Prices for used newspapers in the UK marketplace are said to have edged downwards slightly in the wake of the fire but steady export demand is helping to maintain some strength. However, further reductions are seen as likely in November.

The fire is believed to have centred around one of the plant’s two VariTop winders. Manufacturer Voith explains that “Winders are used to transform the parent reels coming from a paper or board machine by longitudinal slitting of the web into narrower rolls adapted in diameter for downstream processing”.

Speaking after the fire which occurred late on Friday October 7, Norfolk Fire and Rescue Service Norfolk’s chief fire officer Roy Harold said: “We were called to reports of a fire in a paper bale, which is a big roll of paper on a winding drum in the processing plant.

“Huge sheets of paper are wound onto this giant roll of paper, which is like a hay bale. The sprinkler system went off and stopped the fire spreading to the rest of the building, but the fire was inside the machinery which was hard to get to.

“We had 10 pumps on scene plus another 10 specialist vehicles, with about 80 firefighters, including crews from Lincolnshire and Cambridgeshire, as well as from Norfolk. Thermal image cameras were used to check for hot spots.”

Post-fire audit

Last week a “post-fire audit” was carried out between the fire service and Palm Paper. Fire protection staff carried the audit out with David Procter, managing director production at Palm Paper. It was noted that “fire damage is mainly confined to one area of the plant and Palm Paper are working to reinstate the damage to plant.”

In a statement, the parties added: “A combination of Palm Paper’s staff, fixed internal Fire Protection systems and Fire Service intervention helped to mitigate the extent of the damage and extinguish the fire. The cause of the fire was confirmed as accidental ignition of paper. The Fire Service Fire Investigator for the incident was Duncan Ashworth, who worked closely with David Procter from Palm Paper to pull together all the evidence during a joint investigation.”

Sympathy

Within the UK there has been considerable sympathy for Palm. In the mill sector one expert remarked: “This is a competitive world but you never like to hear of a fire at a paper mill.”

Suppliers of paper for recycling to the mill also spoke of their concerns and hopes that the mill would be back fully operational as soon as possible. One said: “This is a modern mill for the UK and we really hope that it is back on its feet soon. It is important for the sector.”

Tonnage

The importance of the mill to the UK is clear in production terms. In January 2015 it passed the 2-million tonne mark for the production of newsprint paper.

At the time company said: “This milestone date is not only the result of the remarkable speed the PM7 machine uses, which is worldwide the largest paper machine for newsprint paper, it is also testimony to the qualification, commitment and dedication of our strong PM7-Team – the second million of paper has been produced in 12% shorter time compared to the first million produced.”

————————————————————————————————————————————————

FIRE CONFERENCE

A conference on fire prevention and control in the waste and recycling industry, organised by letsrecycle.com, is to be held in London on 9 November. More details at: www.fireconf.com

Subscribe for free