Landfill tax research rings alarm bells for SMEs

According to Veolia, if recycling rates do not improve by 2014 this could amount to nearly 1 billion in two years.

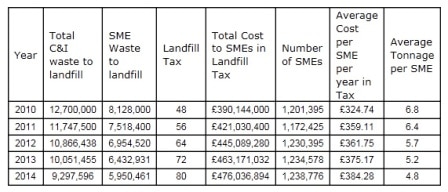

It says the findings should ring alarm bells and reflect that from April 1 2013, landfill tax rose from 64 to 72 per tonne and is set to rise again in 2014/15 to 80 per tonne.

The research found that a typical SME will spend an average of 375 in 2013 on tax by sending waste to landfill, rising to 384 for 2014.

Estelle Brachlianoff, Veolia ES chief executive, said: We have now reached a stage where it is much more expensive to send waste to landfill than it is to recycle. Business need to realise that its not just an environmental decision, its an economic one with immediate benefits to the bottom line. In this time of austerity businesses are throwing money away when they could be more sustainable and reduce their bills at the same time.

The solution is to develop a recycling mindset in the workplace based on segregating materials at source. Working together with SMEs we can put in place new separation processes that take advantage of the latest recycling and recovery technology that are sustainable and bring an immediate financial return.

Oxfordshire publishes details of where recycling ends up

The Oxfordshire Waste Partnership has for the first time published details of where the recyclable materials collected by its local councils end up.

The information sets out the end destinations of Oxfordshires recycling and providing greater transparency on what happens to the countys recyclable waste.

To make the information more digestible recycling officers have put together a graphic which shows what materials go where, and what they get recycled into. The information can be found on the OWP website: www.oxfordshirewaste.gov.uk

Cllr David Dodds is chairman of Oxfordshire Waste Partnership, said:Were incredibly proud of our high recycling rates and want to encourage more people to recycle by explaining the process. We often get asked what happens to the materials once theyve been collected so this handy infographic is a perfect way of illustrating the recycling route.

I hope the graphic shows that our waste is being used as a valuable resource and encourages people to continue recycling or even better to start recycling even more.

Last year, Oxfordshire recycled more than 60% of its household waste, making it the highest recycling county in England. The Oxfordshire Waste Partnership comprises of Cherwell district council; Oxford city council; Oxfordshire county council; South Oxfordshire district council; Vale of White Horse district council; and, West Oxfordshire district council.

Brent awards MRF contract to Viridor

Brent council in North West London has awarded a one-year contract plus an option to extend for a further 12-month period to Viridor to sort mixed recyclable materials arising from households in the borough.

Under the deal, Viridor will sort and market the councils estimated 22,000 tonnes of recyclates at its materials recycling facility (MRF) in Crayford, Kent one of Europes largest MRFs.

The new contract, which came into effect on April 1, will provide residents with further opportunities to recycle, and it is expected to help the council increase its recycling rate. Residents will be able to add all types of plastic containers as well as books and a wider range of metal items to the current mix of glass, plastic bottles, cartons, aluminium and steel cans, mixed paper and cardboard.

June Barlow, Viridors bid manager, said: We already work with many local authorities in the capital helping them recover valuable materials for recycling and we are delighted to have been chosen by Brent as their recycling partner. We are confident that working together, recycling levels across the borough will continue to improve, reducing needlessly disposal of resources and its associated costs.

Councillor James Powney, Brent councils lead member for environment and neighbourhoods, said: “Working with Viridor marks an important step forward for recycling in Brent. This is a deal that provides good value for the council and its residents. Recycling more of our waste will help reduce waste disposal costs and ensure recycling rates are pushed up even higher.”

Wastetransfer station opens in Sandwell

Sandwell council and services firm Serco have officially opened a new 10 million waste transfer station in Danks Way, Tipton.

Eagle Lane Transfer Hub handles more than 1,700 tonnes of waste and recycling each week collected from homes across the borough.The facility is a key part of Sandwell councils 25 year waste partnership with Serco, allowing it to speed up transfer times and deliver a more efficient collection service.

All waste collected from Sandwells residents including domestic, garden and food waste as well as recycling, is taken to the transfer station when collection vehicles are full. Materials are then bulked up and sent to either recycling centre processors or waste treatment facilities.

The site measures more than 23,500 square metres with the main building measuring 4,460 square metres. A new roundabout and road layout have been introduced as part of construction of the transfer station which has the capacity to take up to 200,000 tonnes of waste each year. Other features include three weighbridges and an odour control system.

Councillor Ian Jones, Sandwell cabinet member for neighbourhood services,

said: Since teaming up with Serco in 2010 we have dramatically improved waste and recycling services for residents. Recycling rates have rocketed and were sending less to landfill which means avoiding expensive landfill taxes. The opening of Eagle Lane Transfer Hub is another important milestone that underlines our dedication to continuing to improve services in Sandwell.

ELV recycling plant gains ISO accreditation

Axion Polymers has gained ISO 9001:2008 accreditation for the quality management of its shredder waste advanced processing plant (SWAPP) at Trafford Park, Manchester.

Designed and operated by Axions in-house engineering team, the plant is capable of recycling over 95% recycling and recovery of materials from end-of-life vehicles (ELVs) ahead of the 2015 EU ELV recycling and recovery target, according to Axion.

Non-metallic fractions from the equivalent of about 800,000 cars a year are separated at the multi-million pound facility, which opened in January 2011, through a combination of plastics recycling, producing materials for the construction industry and fuel to substitute coal.

Axions health & safety environmental manager, Adam Joyce, who led the implementation of the system, said: The ISO 9001:2008 is an internationally-recognised standard for the quality management of businesses. It demonstrates that we run an effective quality management system and that we are committed to quality, our customers and to a process of continuous improvement.

Further processing of plastic concentrate at Axion Polymers Salford plant creates a range of plastic chip and extruded pellets for a wide range of customers, including some in the automotive sector, thereby closing the recycling loop.

A further 1 million was invested in 2012 as part of on-going efficiency optimisation at the SWAPP, which has an annual 200,000 tonnes processing capacity.

Subscribe for free