FCC highlights EfW power capacity during cold weather

Residents in Lincolnshire have been invited to visit the county’s energy from waste (EfW) facility to see how the plant will provide power to the local grid and help to heat homes this winter.

The EfW facility, run by FCC Environment, treats 170,000 tonnes of residual household and commercial waste each year and provides enough energy for around 26,500 homes.

FCC general manager Juergen Schaper, said that the cold winter weather provides an ideal time for residents to visit to learn about the potential for the plant to produce energy for homes.

He said: “When the temperature drops we use additional power to keep our homes warm and powering up our homes doesn’t happen by magic.

“The technology we have in place here is making a real difference and providing fast-paced energy generation.”

Residents are invited to visit and find out more about the technology at the Lincolnshire EfW site visitor centre, which provides educational tours of the plant.

Cllr Reg Shore, Executive Member for Waste and Recycling at Lincolnshire county council, said: “The visitor centre at the Energy from Waste site is ideal for people to learn more about the new technology and the positive effect it’s having on Lincolnshire, both in terms of reducing the waste we send to landfill and the energy benefits it is creating.

“It’s perfect for school, college and community groups to visit, and I hope more people will get involved.”

_______________________________________________________________________________________

Biowood puts recycling message at the top of the Christmas tree

Ilkeston-based wood recycler and biomass producer Biowood Recycling is taking the recycling message to its local community through a Christmas tree made entirely from waste materials.

The five-and-a-half-foot tree was designed and constructed by Biowood’s commercial director John Walls, using items destined for recycling or landfill.

The tree combines an old snooker cue, broken gazebo poles, a battered badminton racquet and some defunct racing bike handlebars.

Mr Walls said: “2016 has seen a dramatic increase in the amount of non-wood waste that Biowood has handled and now it contributes to approximately 50% of our total business.

“At this time of year especially, we (as a nation) create an extraordinary amount of waste, and it occurred to me that it might be an appropriate time to really drive the message home about how we can all do more to prevent household waste being sent to landfill.

“My daughter’s Pre-School enters a Christmas tree in the local festival every year and I thought that it might be an interesting way to showcase everyday waste in a different form, whilst highlighting recycling and re-use as an important issue”.

The children from Cranmer Pre-School in Aslockton, Nottinghamshire have created decorations to hang on the tree, from more household waste items such as yoghurt pots and toilet roll tubes.

The tree will be on display at Aslockton Church as part of their Christmas Tree Festival, and after that will be taken to Biowood’s offices in Ilkeston, Derbyshire.

_______________________________________________________________________________________

ACE UK achieves wood fibre traceability milestone

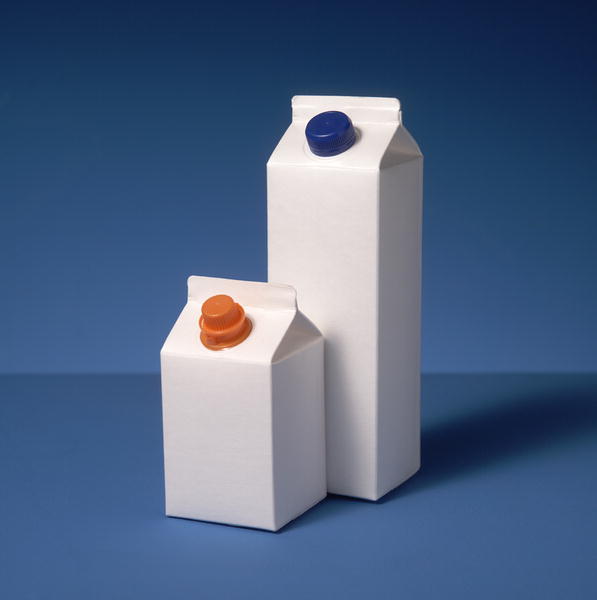

Carton recycling organisation ACE UK has announced that it has met its Chain of Custody (CoC) commitment to source 100% traceable wood fibre by the end of 2015.

The Alliance for Beverage Cartons and the Environment (ACE) members – Tetra Pak, Elopak and SIG Combibloc – made the CoC commitment in 2007. Wood fibre is one of the main raw materials used in the production of cartons – which is used in the form of paperboard, and comprises around 75% of the product.

ACE UK’s members set a target in 2007 to source 100% of its wood fibre from traceable to fully third party verified sources by the end of 2015.

All sites involved in the production of cartons are now Chain of Custody certified, the organization has claimed.

Richard Hands, chief executive of ACE UK, said: “When we set the target in 2007 we knew it was an ambitious one, so it is great news that the 100% target has been achieved and independently verified.”

He added: “Traceability is one of our industry’s key strategies in ensuring the responsible sourcing of primary raw materials, which is, in turn, critical to achieving sustainable economic growth. Achieving this target really is an important milestone for the food and drink carton industry.”

_______________________________________________________________________________________

Eunomia researches circularity across EU furniture supply chain

Waste and resources consultancy Eunomia has been commissioned by the European Environmental Bureau (EEB) to undertake research into the effects of integrating circular economy principles across the European furniture supply chain.

According to Eunomia, in Britain alone some 300,000 tonnes of reusable furniture is thrown out every year.

The research will aim to identify key interventions and policy levers to accelerate a circular economy in the furniture sector.

According to the European Federation of Furniture Manufacturers (UEA), EU furniture waste accounts for more than 4% of the total municipal solid waste, of which 80-90% is incinerated or dumped in landfills, with only 10% recycled.

The research will explore the impacts of adopting eco-design principles, incentivised return, leasing and take-back models, and shifting production towards greater use of secondary materials, and refurbished components and units.

Eunomia founder and chairman, Dr Dominic Hogg said: “There is a long list of potential benefits to developing a more circular furniture supply chain. Some of them are environmental, such as significantly reducing reliance on the extraction and input of raw materials, and reducing greenhouse gas emissions as a result.

“But there are economic benefits too: a more circular supply chain promotes growth and jobs in emerging service areas such as repair, reuse, re-manufacture and leasing.”

Subscribe for free