The report says that Scotland exports ferrous scrap to countries such as Turkey, although one of Scotland’s large metal recycling businesses says scrap goes primarily to continental Europe. And, the metals recycling sector’s trade association was not consulted on information for the report.

The ZWS report was the second of its type from the Scottish Government-backed body to endorse the idea of building a new Electric Arc Furnace (EAF) steel mill in Scotland which would use ferrous scrap as its feedstock.

Such a development would be a significant project for the UK and Europe but would fit in to the circular economy aspirations of Zero Waste Scotland.

Emissions

The study was published on 25 October, and claimed that by developing an EAF plant for scrap steel in Scotland, “emissions from material, transport and energy use could be reduced substantially.”

[updated 24 November, see end of article for Zero Waste Scotland update]

Dr Charlotte Stamper, Partner for Energy Infrastructure at Zero Waste Scotland and co-author of the report, said: “Our findings show that Scotland exports almost 820,000 tonnes of scrap steel per year for remelting in other countries. In many of those places, they still use methods which require large amounts of coal and the addition of virgin iron ore to operate – and this carries a high carbon cost.

“If Scotland were to instead invest in modern Electric Arc Furnace technology, we could operate these using 100% scrap and power them using Scotland’s low carbon electricity rather than coal. We would also no longer export valuable materials, strengthening Scotland’s resilience by securing domestic steel supply chains are in place to keep Scotland’s economy running in times of global material shortages.”

Precising the report, on Twitter, Dr Stamper explained that Scotland exports its scrap steel to other countries (like Turkey and China) in many cases to be smelted using coal. “A clear example of how #netzero is not zero.”

Today, Scotland exports it scrap steel to other countries (like Turkey and China), in many cases to be smelted using coal. A clear example of how #netzero is not zero.

At the same time, steel is vital for our #energytransition, including #offshorewind. Time to close the loop! https://t.co/GCicsRUIZP

— Dr Charlotte Stamper (@C_Stamper) October 25, 2021

Dr Stamper also said that a new steel mill would “keep Scotland’s economy running in times of global material shortages”.

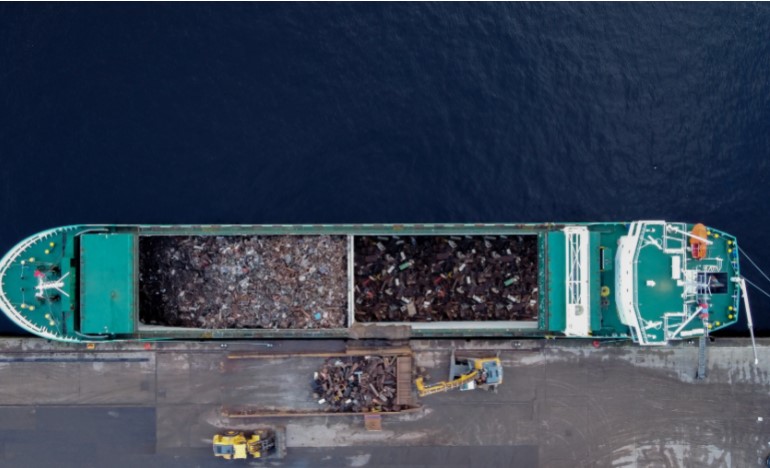

Now, one of the large Scottish metal recycling business John Lawrie Metals has slammed the report saying it is “fundamentally flawed in that the destination of processed steel scrap from Scotland is mis-stated as going to blast furnace steel mills in Turkey, when the majority is shipped by the short-sea market to steel mills in continental Europe.”

‘Curious’

Antonia Grey, head of policy and public affairs at the British Metals Recycling Association, told letsrecycle.com: “It was curious that they did not consult with ourselves or anyone and came to these conclusions without the experience of the industry.”

In a detailed response to the ZWS study and its content, John Lawrie Metals said that the steel mills in Europe all operate with electric arc furnaces (EAF) using 100% scrap steel, most of which use energy from renewable energy grids. Disappointingly, the report makes no mention of these destinations.”

The claimed emissions and energy savings in the report are significantly overstated

– John Lawrie Metals

John Lawrie continued: “Consequently, the claimed emissions and energy savings in the report are significantly overstated, as they are compared to blast furnaces which typically use small volumes of scrap steel (c18%) mixed with virgin iron ore and powered with high volumes of coal.

“The report also states that by having a steel mill in Scotland it will save transport and energy emissions over current processes. However, by shipping in bulk (typically 5,000 tonne shipments) to continental Europe minimises energy and emissions over transporting by road. In the event of a steel mill being built in Scotland, this would require all of the 820,000 tonnes per annum of processed scrap stated in the report being transported by road, resulting in an additional >68,000 heavy vehicle return road journeys throughout Scotland’s road network with the associated fuel, emissions and road risk. It’s hard to see where this would contribute to achieving Scotland’s net zero aspirations.”

Dataset

The company continued: “The dataset used in the ZWS report is taken from a Bureau of International Recycling Report (BIR) in 2018, which refers to the UK scrap market as a whole and does not break down into Scottish scrap arisings and destinations.

“We have discussed the content of the report with ZWS and made them aware of our comments and concerns. It is regrettable that no attempt was made to engage with the scrap metal processing industry at the outset, as the information specific to Scotland can be made available, which would have made the report outcomes more relevant. ZWS has subsequently acknowledged this and we are working with them through the British Metal Recycling Association (BMRA) and its members in order to produce a more meaningful outcome.”

Zero Waste Scotland response

In a response, available in full HERE and reproduced in part below, ZWS noted the benefit of some clarification and that companies in the metals sector are taking actions to reduce the carbon impact of what happens to their steel.

Subscribe for free