The concept of a circular economy is being driven faster than ever before, and as such is gaining significant traction with a number of large and well-known brands.

This is largely in response to increasing constraints on resources – the raw materials of any business – and the need to use these resources more sustainably, for both environmental and economic reasons.

Today there are a number of key threats facing businesses across the UK, including:

Economic

– Waste is an increasing cost to business – collection, treatment and disposal;

– Raw material prices are rising, so wasting these resources is more costly; and;

– There is only one planet’s worth of resources, yet we use more significantly than this and time is running out to redress this balance.

Social

– There is the potential loss of jobs if manufacturing companies cannot secure an affordable, reliable supply of raw materials and thus cannot compete in their markets; and;

– Potential increased food and material poverty if household food and everyday items become too expensive for segments of the public to buy.

Environmental

– Increased raw material mining and associated environmental impacts is becoming a major global concern and has hit the headlines recently;

– Rising global greenhouse gas levels due to our high consumption levels is threatening the planet; and

– Continued destruction globally of wildlife species because of habitat loss caused by our high consumption levels of specific products / raw materials.

In response to these increasing concerns many businesses are now opening themselves up to adopt more ‘circular thinking’, with the economic threats of increasing raw material costs and higher waste management costs at the forefront of this shift in attitude. Big businesses, with large supply chains, significant raw material costs and back-end waste management costs have been the first movers towards greater circularity, recognising the obvious benefits of keeping materials ‘alive’ in their economic system for longer. The press has been full of stories in the last few years about the likes of Coca Cola, IKEA, Sainsbury’s et al making significant strides to improve their supply chains and close the loop with their waste products.

Circular thinking (and subsequent action) will result in the development of a more resilient economy which is better protected against resource supply risks and commodity price fluctuations, but will also enable job creation and deliver environmental benefits associated with closed loop recycling of materials. It’s a win-win, but still much of UK industry and commerce remains unaware of the opportunities or the support that is out there!

But what about SMEs and their adoption of circular thinking?

Small businesses are the backbone of the UK economy, and represent over 99% of businesses. As such they are key to the successful adoption of a future UK circular economy, one where many materials and products are re-circulated, recycled, and re-used, but they have not been at the fore of the shift towards more circular business models thus far.

SMEs are increasingly aware of the benefits of improving resource efficiency, a message that has been actively promoted across the UK for the last 20 years or so through active Government programmes like Envirowise and WRAP’s Business Resource Efficiency support package, through to the current Zero Waste Scotland led Resource Efficiency Scotland programme. They know that reducing raw material usage and saving material costs, and the benefits of increased recycling make sense financially and from a public relations perspective. But still many have failed to actively implement change.

Whilst an increase in recycling is an essential component of a move to a circular economy, reducing the use of resources through alternative business models has the potential to make a much bigger impact. Circular Economy Business Models (CEBMs) are more aligned with the top of the waste hierarchy – enabling waste prevention and reuse. A circular economy requires a more systems-thinking led approach and an increased focus on specific areas of “circularity” – i.e. repair, remanufacturing and the sharing of resources. This provides a real opportunity for SMEs to access new markets and create competitive advantages. A few examples of CEBMs include:

– Service systems – providing a service based upon delivering performance outputs that are linked to products or services. Products could also be designed for disassembly, remanufacture and re-use. Under this approach the manufacturer retains ownership, and thus has more interest in producing a more durable and reliable product. Examples include Philips’ ‘pay per lux’ service and Juice’s leasing model for lighting .

– Hire and leasing – long term hire and leasing to drive a longer service life and to increase product durability – leasing of IT equipment is a common example of this.

– Collaborative consumption – rental of products or services between organisations/consumers where each partner only needs limited use of the service/product, for example AirBnB and agricultural machinery rings.

– Incentivised return and reuse – encouraging the return of used items through take-back or re-use schemes, for example Re-tek repairs and refurbishes functional used IT products and sells on to new owners, sharing the revenue with the previous owner .

– Asset management – improving the internal management of items, by collection, re-use, and refurbishment or resale, and we have delivered a project which looked at opportunities for increased re-use within universities, as well as potential for resale and re-use of redundant equipment.

– Collection of used products – collection by a service provider to ensure products/materials are passed on to an appropriate re-use system, and there are a number of organisations that provide bulky waste collections from households, and then refurbish and repair items for resale.

– Long life – products designed to have a long life time with durability, reducing overall consumption and raw material mining, for example Patagonia aim to make clothing with a long life and also provide a repair service.

– Made to order – manage production to minimise material requirements and avoid potential losses from over-stocking products, for example Duo Boots make boots to size and order depending on customers measurements.

– Valorising waste products – maximising the value from waste, where we have been working with a brewery in Scotland to understand the opportunities for diversification through investigating alternative uses for by-products from its process.

Barriers to adoption?

There are increasing opportunities to adopt alternative systems, and many public sector organisations are actively adopting sustainable procurement principles thus creating new opportunities for business to propose alternative business models in their outline solutions to the public sector. However, there are a number of barrier that SMEs face in terms of the current development of CEBMs, including:

– Lack of financial resources: The upfront costs of any type of investment and the anticipated pay-back period are key aspects for SMEs, as they are generally more sensitive to additional financial costs, particularly in the recent economic climate, and may not know about possible funding sources.

– Time and resource constraints: SMEs often don’t have sufficient staff or time to research and investigate alternative business models.

– Lack of awareness/ knowledge of the potential benefits: because they are ‘flat out’ delivering on a daily basis they may not have researched or appreciate the opportunities that are out there.

What is needed to drive change?

There are three critical areas that are vital to drive the adoption of circular thinking amongst SMEs. These are:

– Provision of technical support to SMEs to assist them with the initial thinking and action;

– Clear drivers and signals from government that lead the direction of travel, and;

– The inclusion of circular economy principles within public sector procurement processes.

There a number of programmes of support being delivered in parts of the UK to support SMEs to identify opportunities that the circular economy can provide to their business, including national programmes such as the Zero Waste Scotland Resource Efficiency Advisory Service and their grant funding support available via the Circular Economy Investment Fund, WRAP’s REBus project, as well as regional examples such as that provided in London by LWARB. Indeed the specialist consultants in our circular economy team has provided support to a range of organisations and sectors through these programmes commissioned by both WRAP and Zero Waste Scotland.

The provision of such technical support particularly around CEBMs is vital for engaging these businesses due to the time and resource constraints that SMEs often highlight as a key barrier to any form of research or investigation into business changes, and it is important that this support continues, targeting specific sectors where CEBMs are most suited and the momentum can be built quickly, including the automotive, electrical items, and construction sectors.

It is also critical that any programme of support provides materials to promote the successful outcomes of the support provided, through the use of social media, articles in the trade press, case studies etc. – success breeds success! In presenting the outcomes of this type of support, it is vital that barriers are openly discussed and how they were overcome, and the benefits presented from an economic, social and environmental perspective. It is also important to use language that SMEs consider as relevant to their business rather than terms such as ‘circular economy’ as this may not be readily understood.

Further drivers to encourage the development of a circular economy are also needed; Scotland and Wales have strong policies in place to encourage the development of the circular economy, in conjunction with the provision of technical support but this is not the case in England. However, Defra has confirmed that it is working under the assumption that the EU’s Circular Economy Package will apply to the UK, which may provide additional drivers and more certainty to businesses for investment purposes.

Public sector procurement also has a key role in driving change through the supply chain, through the inclusion of circular economy principles within the procurement process; thus driving SMEs to consider change as a means of securing public sector contracts. But as highlighted previously, the language used within procurement documents must avoid terms that may not be familiar to SMEs.

Looking ahead

Providing practical examples of the circular economy in action, and at various scales and in different sectors, is vital to gain traction amongst SMEs of the benefits that the circular economy can provide. However, we also need to provide sufficient resources and networking opportunities so that SMEs can explore the benefits of circular economy opportunities themselves and with their supply chains. And for that to work effectively we need a strong government agenda, supported by programmes designed to engage, enlighten and encourage SMEs to think and act differently. With this type of programme in place the progress being made in London and Manchester and Leeds, and the obvious ongoing success in Scotland could be replicated across the UK and ore widely across England in particular, which is where many of us believe the real need and opportunity lie.

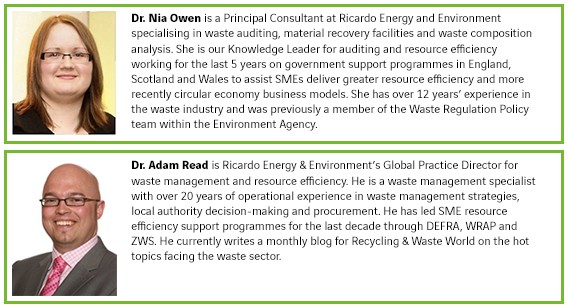

About the authors

Subscribe for free