The Canadian firm has been appointed to provide the machinery by global engineering company M+W Group, which is constructing the plant on behalf of waste management firm Levenseat Ltd.

Announced earlier this month, the £111 million ‘first of a kind’ energy from waste (EfW) plant and adjacent materials recycling facility (MRF) will be built in Forth near Lanark. The 12.5MWe facility is being partly financed by a £28.25 million investment from the Green Investment Bank, as well as investment from Levenseat Ltd and senior debt from Investec Bank plc (see letsrecycle.com story).

The sorting line will provide refuse derived fuel (RDF) and solid recovered fuel (SRF) for the EfW plant, which is designed to process 42 tonnes of commercial and industrial waste per hour as well as municipal solid waste.

A minimum of 100,000 tonnes per year of RDF feedstock for the EfW plant will be produced by the MRF, which will also separate paper, cardboard, plastics, metals and wood to divert from landfill.

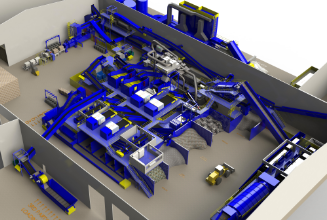

According to Machinex, to meet the objectives of the facility, the firm will use four shredders, one Machinex trammel, one waste screen, three air separators, two Machinex ballistic separators, three Machinex MACH Hyspec optical sorting units, one fluidised bed dryer and two Machinex single-ram balers.

The fluidised bed drying technology is a self-sustainable continuous dryer that will use the heat generated by the EfW plant to help dry the wet organic waste used in the production of RDF, Machinex said.

Project director at Machinex, Jonathan Menard, said: “In my opinion, the system incorporates the ideal balance between the generation of controlled and homogeneous RDF and SRF products, while maximizing the capture of high value recyclates, and ultimately significantly maximizing the waste diversion to landfill. The flexibility of the design is an outstanding feature of this system as it offers an impressive number of options to the operator when dealing with the inevitable constant variation in waste input.”

Pierre Paré, chief executive of Machinex Group, added: “We are delighted to have been selected for this first-of-kind project in Scotland. This project will allow Machinex to once again reaffirm its expertise and capability in the fuel preparation market. For us this project represents a significant milestone in our European business development. We warmly welcome M+W Group and Levenseat Renewable Energy Limited into the Machinex family and look forward to making this project a real success.”

Levenseat

Angus Hamilton, director at Levenseat Ltd, said: “We are really looking forward to working with Machinex on delivering this project. All throughout the tendering process we were impressed with Machinex’s enthusiasm, they listened to and understood our requirements and produced a design that aligned perfectly with what we were aiming to achieve. For this project we required a robust yet flexible solution, we found in Machinex an organisation that shared this passion, not afraid to think outside the box, therefore making them the obvious choice to supply our new advanced material recycling facility.”

Subscribe for free