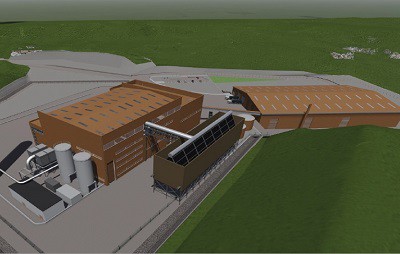

The £111 million plant is being developed by Levenseat Renewable Energy Ltd – with backing of around £28.25 million in backing from the Green Investment Bank and includes a materials sorting and RDF production facility alongside a combined heat and power (CHP) EfW plant (see letsrecycle.com story).

The facility has been designed to process up to 42 tonnes of commercial & industrial waste per hour along with municipal solid waste at the front end, producing ‘a minimum’ of 100,000 tonnes of refuse derived fuel (RDF) per annum to be burned in the adjacent energy facility.

Sorting

The sorting plant will have the capacity to process close to 200,000 tonnes-per-year of material – with the capability to remove recyclable materials such as paper, cardboard, plastics, metals and wood from the RDF stream.

The system will also produce a Solid Recovered Fuel (SRF) stream from the super-light and high calorific non-recyclable waste commodities.

Canadian company Machinex was contracted by engineering firm M+W Group, to provide MRF equipment for the site, which is currently being installed and is expected to be operational in early 2017.

Equipment

Machinex is installing four shredders, a Machinex trommel, a waste screen, three air separators, two MACH Ballistic separators, three MACH Hyspec optical sorting units, a belt dryer and two Machinex single ram balers.

One of the balers will be used for recyclable commodities, while the second baler will be dedicated to handle RDF and SRF bales. This model was developed by Machinex specifically for the waste to energy industry to handle RDF baling, and incorporates plastic strapping and bale wrapping as part of the RDF solution (see letsrecycle.com story).

To ensure the quality of RDF recovered from the stream of fines, which includes wet organic waste, belt drying technology is also being installed. The continuous dryer is self-sustainable and will use heat generated by the waste to energy plant adjacent to the MRF to operate. The addition of a drying solution is scheduled to be operational in mid-2017 to complete the project. The company has said installation is progressing as scheduled.

Levenseat

Levenseat Renewable Energy – has been set up by Scottish recycling & waste management firm Levenseat Ltd, a commercial and industrial waste processor, operating from a site at Forth, Lanark. The company was established in 1985.

The renewable energy arm was established in 2014 specifically for the energy project with external investment provided from funds managed by Zouk Capital LLP and Foresight Group LLP, with debt from Investec Bank plc.

Angus Hamilton, director at Levenseat Ltd, said: “We have been very impressed with Machinex as a company, they were more than willing to work with us to find an appropriate, robust and creative solutions for our project.

“They have been very professional and have shown a dedication to not only completing the project on time but also making sure we were satisfied throughout.

“Above all we felt Machinex really listened to and understood our requirements and worked with us to produce a design that aligned perfectly with what we were aiming to achieve.”

US energy technology firm Outotec is developing the technology for the waste-to-energy plant – with a fluidized bed system to be employed – due to be operational by mid-2017.

Subscribe for free