The switch to an electric Kentek machine boosted capacity and also helped the company cope with the ending of red diesel for composting equipment.

GBRS, which was established in 2005, has explained that it was was under pressure in coping with the increasing volumes of garden waste needing to be processed at its site near Bedford. It receives green waste from various sources, including builders, landscapers and local authorities.

Composting

The material is shredded and placed onto a block composting system for maturing. The maturing material is turned regularly using the latest windrow turning technology until its composting cycle is completed. Once the material has matured, it is screened into different fraction sizes providing various specifications of compost.

As its company and facility has grown, the volume of green waste GBRS receives had increased. Its previous screening process consisted of two mobile trommel screens and it was felt that a new screening solution was required.

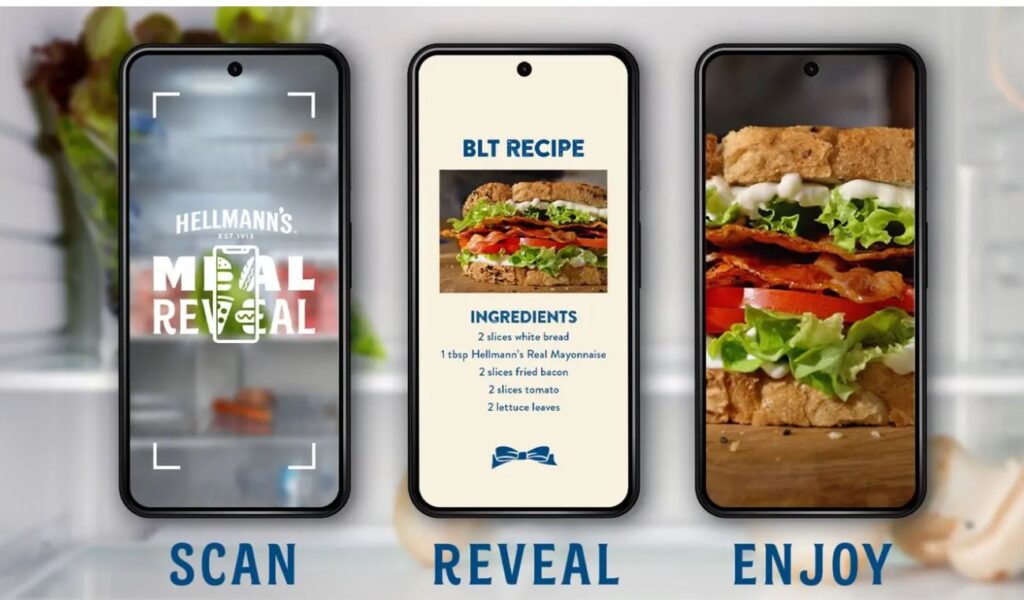

(above on YouTube, the Growing Beds site with the Kentek dual trommel

GBRS explains that it took the opportunity to increase its screening capacity and introduce, what it says is a simpler, more cost-effective solution that reduced moving parts and energy costs. Mark Evans – director at Growing Beds Recycling Services, approached Mike Symons – area sales manager at CRJ Services, to discuss his requirements. With knowledge of GBRS Mr Symons proposed a static electric dual Kentek XD620S trommel plant, including a feed hopper.

Red diesel

Mr Symons said: “This has been a great project to be a part of. It has been our first time supplying a Kentek trommel system, which I predict will become a popular option for our customers. With the removal of the red diesel subsidy in April, and the recent increase in white diesel costs, the electric trommel provides a lower processing cost per tonne compared with the previous diesel-driven screeners. It is great to see our first solution delivering great results for Mark and his GBRS team.”

Following the commissioning of the plant, Mr Evans commented: “The new static trommel plant is straightforward to operate and is probably doing double the tonnage compared to our mobile trommels.”

The two screeners are fitted with 10mm and 25mm trommel drums, which he said, produce a top-quality PAS100-accredited compost product. These final compost products are then sold back into the agriculture, horticulture and domestic compost market.

Subscribe for free