Joshua Doherty examines what the term means and the impacts it could have on councils, waste firms and industry.

The concept of ‘full-cost recovery’ was outlined in the EU’s Circular Economy Package (CEP), with a requirement to reach a minimum of 80% by 2023.

This means that producers must be responsible for at least 80% of the cost of dealing with the packaging they place on the market. Currently, most estimates have placed the current figure in the UK at between 10-20%.

A much higher figure would mean a “transfer of costs”, partly from local authorities and the waste and recycling chain to the producers, which could well see the two ‘sides’ battle over the costs of treating packaging placed on the market.

At the moment, Defra is in discussions about how this is exactly worked out, with debate surrounding the scope of the costs and exactly how they are calculated. Estimates by some in the industry have put this figure at between £500 million and even as high as £1 billion, as the costs involved.

Targets

As the UK already meets many of the individual material recycling targets set in the CEP , it has been suggested that it may wish to go beyond some of what is laid out in the proposals, which could include even going for 100% full cost recovery.

However, the exact methodology of how this is calculated remains unclear. EU law generally dictates what the end goal must be, along with targets and some legislation, but member states do have some flexibility on how this is achieved.

“Full cost recovery generally includes contributions, in some form, to the collection, transport, treatment and getting the information out there to recycle material correctly,” explained Duncan Simpson, director of sales and marketing at Valpak.

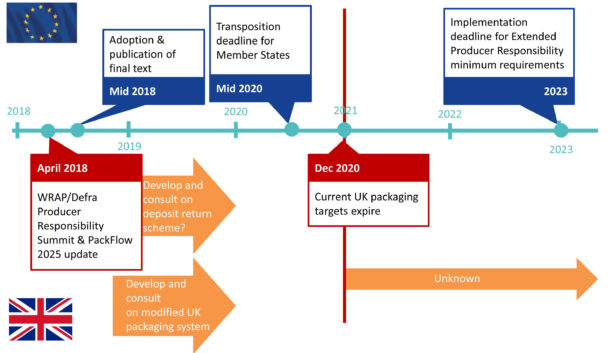

He added that it will take time to resolve this: “The latest we will see these regulations is 2023, as that is the deadline set out.”

Consideration

When discussing the waste strategy in a talk at the RWM exhibition, Defra official Paul Bradley said the department “is and will be considering” full cost recovery as part of packaging reforms. He explained that Defra will be launching a string of consultations in the coming months, with the waste strategy itself largely outlining what will take place.

It means that Defra will have time to consult and it’s believed the concept of ‘full cost recovery’ is being looked at in three ways through changes to the current PRN system.

One will be a similar ‘free market’ approach where producers pay upfront, with the money then refunded once proof that it has been recycled is provided, similar to the PRN system now.

The second will see a central body established to collect data and then put in place contracts with local authorities, other waste collectors, sorters and reprocessors to collect and recycle packaging and deliver the necessary evidence. Once added up, the cost is centralised and split up amongst producers.

The third is similar to the WEEE system and will see each producer given a market share which it then must recover through joining one of a number of collective compliance schemes. So for example, a company putting 10% of packaging on the market must then recover 10% of material as well, and likely be charged per tonne if it misses the target.

From Valpak, Mr Simpson said: “We need an approach with the best way to reduce contamination in the long run, and we need investment in re-processing and collection.

“Each system has its own sets of pros and cons, so we need to ensure that any system implemented actually ends up having the desired effects.”

And his colleague Adrian Hawkes, policy director at Valpak noted: “One of the key challenges is going to be designing the future system to ensure that there are sufficient incentives to improve cost effectiveness and quality of material collections over time rather than simply passing the bill for what happens now on to producers. If producers are to take on a much greater share of the costs then they will wish to ensure that there will be a drive to more consistent and more efficient collections of packaging for recycling in future, as well as incentives for investment in high quality reprocessing infrastructure in the UK.”

Retail

Speaking with letsrecycle.com, Alice Ellison, environment policy advisor at the British Retail Consortium, the trade association for the UK’s retail industry, explained that while the sector accepts the fact it will have to pay more, it needs to be done in a careful way.

“There is no set clear cost than can be spread out evenly, as such. We have the PRN system but the entire cost for local authorities can be quite difficult to calculate as it takes various forms. In the long-term, it is crucial that retailers know how everything will work together. We have PRN reform, EPR and DRS regulations all coming in. It means potentially retailers, if the process isn’t thought out, could be hit with three sets of costs.

“There is an acceptance among our members that this could be a game changer, and costs to producers need to rise. However, if costs do rise by a lot, they would want to be more involved in where this is spent.”

Ms Ellison went on to say there are already low margins for retailers on food, and with the struggles faced by the high street at the moment, the impact of a process being implemented wrongly could be catastrophic for both consumers and business. She added that there is no guarantee that council tax would necessarily fall either.

Audit Office

When discussing the concept of full cost recovery for general policy making , the National Audit Office says that the “common principle” of full cost recovery includes calculating “the total management cost for the third sector organisation (TSO), including elements such as governance, strategy and policy, human resources, finance and quality assurance”.

The NAO added that this includes to “apportion the total management costs across the TSO different programmes of work in proportion to the size of each of those programmes. In doing this, you must make sure that the apportioned costs are fair and reasonable. For example, a volunteer’s time should not be included but the cost of managing volunteers should be.”

Audit Committee

In an Environmental Audit committee sitting earlier this month, committee chair Mary Creagh asked Lee Marshall, chief executive of local authority group LARAC, about full cost recovery and what would it mean.

He responded by saying there were two aspects to it, one that it will allow better and wider collection schemes to be introduced so we can collect more materials from the public and also help achieve more engagement with members of the public; but also support infrastructure as well.

Phil Conran, chair of the Advisory Committee on Packaging, echoed this by saying that requiring full net cost recovery to producers, it is going to increase their costs, “people are talking about five or ten times what their current costs are and that will certainly make producers and retailers sit up and look at what they are producing and packaging”.

Industry response

Calls for this level of increased burden on producers have been about for a long time as well as indications that some of the producers recognised the need to put more funds into the system. INCPEN – the Industry Council for Packaging and the Environment – have been on record to say that they support the idea of paying more, explaining that “businesses have been clear that they are willing to pay more into a packaging producer responsibility system to ensure that it is adequately funded and works effectively”.

However, the exact full cost of this is difficult to ascertain, according to Robbie Staniforth of compliance scheme Ecosurety, who also said that Defra should be the ones to look at working out this figure.

Speaking with letsrecycle.com, he said: “The value of full cost recovery is very difficult to know. We know from PRNs, or can roughly indicate the cost of that, but knowing council spend is hard with costs and rebates on top of collection costs.”

Mr Staniforth added: “Total number of net cost ranges from around £500 million to £1 billion. It could be anywhere in that range – finding out this cost is work that only Defra can do. The concept of full cost recovery has triggered debate but not particularly well understood.”

Suez

Others across the waste management industry have also had their say on the concept of full cost recovery and the scope it would cover.

Suez, for example, said in a report on EPR earlier this month that if the UK government was to seek 100% full cost recovery for obligated items, “then this may contribute towards the cost of dealing with litter and residual waste treatment”.

“Governments considering EPR will often attempt to set a level of cost, to producers, of placing target products on the market cost, which ensures recycling is less expensive than the cost of the charge itself, while also setting targets for recycling which allow progressive and measurable delivery,” the report said.

Subscribe for free