Researchers at the University of Leicester are said to have achieved a “major milestone” in fuel cell recycling, which more specifically involves separating valuable catalyst materials and fluorinated polymer membranes (PFAS) from catalyst-coated membranes (CCMs).

This development addresses critical environmental challenges posed by PFAS – often referred to as forever chemicals.

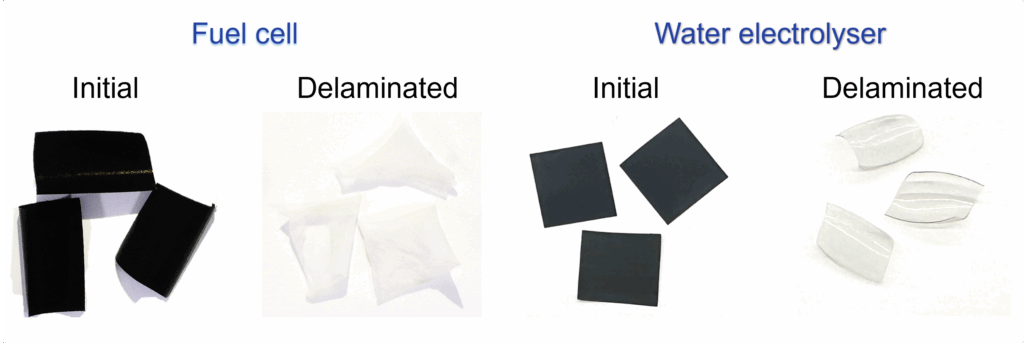

Fuel cells and water electrolysers, essential components of hydrogen-powered energy systems, powering cars, trains and buses, depend on CCMs containing precious platinum group metals. However, the strong adhesion between catalyst layers and PFAS membranes has made recycling difficult.

Dr Jake Yang from the University of Leicester School of Chemistry said: “This method is simple and scalable. We can now separate PFAS membranes from precious metals without harsh chemicals – revolutionising how we recycle fuel cells. Fuel cells have been heralded for a long time as the breakthrough technology for clean energy, but the high cost of platinum group metals has been seen as a limitation. A circular economy in these metals will bring this breakthrough technology one step closer to reality.”

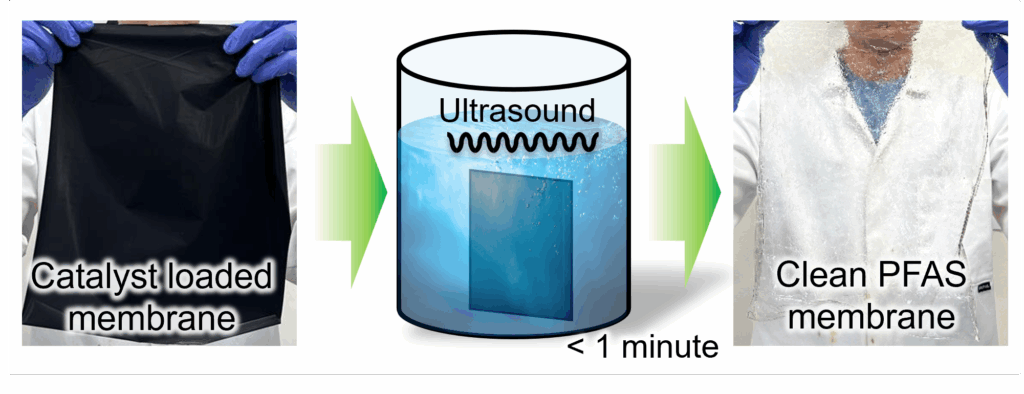

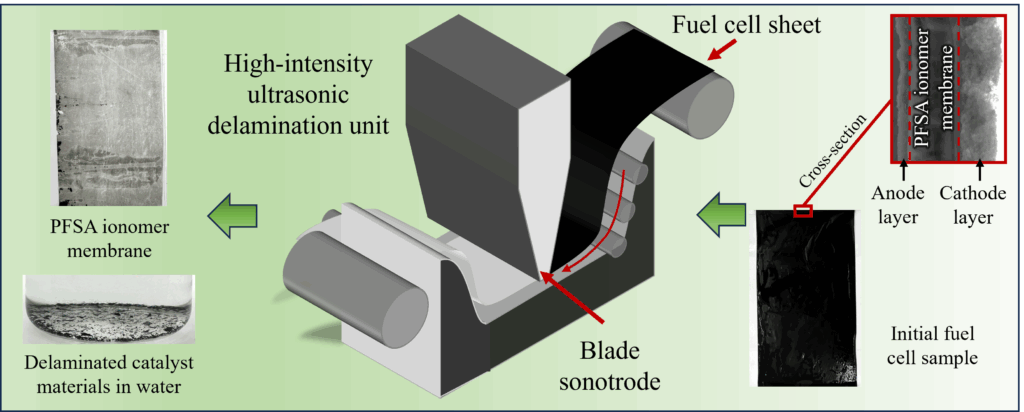

Building on this success, a follow-up study introduced a continuous delamination process, using a bespoke blade sonotrode that uses high frequency ultrasound to split the membranes to accelerate recycling.

The process creates bubbles that collapse when subjected to high pressure, meaning the precious catalysts can be separated in seconds at room temperature. The innovative process is both sustainable and economically viable, paving the way for widespread adoption.

The research was carried out in collaboration with Johnson Matthey. Ross Gordon, principal research scientist at Johnson Matthey, said: “The development of high-intensity ultrasound to separate catalyst-loaded membranes is a game-changer in how we approach fuel cell recycling.”

Subscribe for free