TOMRA to boost sorting at five EfW plants

TOMRA Sorting Recycling has been selected as the technology partner of choice for five new energy from waste (EfW) plants across the UK.

TOMRA’s customers have chosen to invest in the sensor-based sorting specialist’s technology in order to divert material from landfill and maximise the recovery of end fractions from municipal solid waste.

The new contracts will see 23 of TOMRA´s AUTOSORT units and one X-TRACT, TOMRA´s X-ray transmission unit installed across the five new plants to recover high purity films, plastics, paper, and inert material and create a fuel from non-recyclable residual materials.

Projects include FCC’s 55tph mechanical biological treatment (MBT) plant in Wrexham, North Wales, a new 90tph MSW plant in the south of England, an MSW plant in North England, and a new 70tph MSW plant in the North East.

Steve Almond, sales engineer at TOMRA Sorting UK, said: “Our customers are certainly embracing the benefits that sensor-based sorting technology offers when used in MSW plants. With the EfW sector facing pressure to build more cost-effective and energy efficient plants, we believe fuel preparation using residual material will be a significant growth area.”

_________________________________________________________________________________________

Helistrat selects Middleton Engineering baler for recycling operation

UK-based contract management partner Helistrat has deployed a Middleton Engineering baler as part of a recycling operation for a new retail distribution centre.

The fully automated Scapa HB60 HM3 channel baler, designed and manufactured by Middleton Engineering in Somerset, forms part of an inbound goods waste packaging recycling stream.

It is linked to an automatic conveyor feeding waste cardboard packaging from goods received at the warehouse and decanted into storage.

At peak volume, the solution is designed to handle some 1200 waste cartons per hour. Baled waste is then sent to re-processing mills.

According to Helistrat, key factors in selecting the Middleton Engineering solution were its ability to overcome some challenging site constraints with a difficult layout, while delivering the performance requirements and throughput needed to service the facility.

Mark Smith, engineering director at Middleton Engineering said: “The Scapa HB60 is an extremely reliable baler, incorporating our proven hydraulic wire tying solution to produce consistent high quality bales. Its small footprint and low headroom make it an ideal solution for a wide range of recycling environments.”

_________________________________________________________________________________________

Honeywell launches protective needle-resistant gloves

Honeywell has announced Picguard Urban, a new range of gloves that protects workers at risk of needle stick and puncture while offering improved comfort.

Made using reinforced yet thin and light materials, Picguard Urban makes the use of overgloves unnecessary, offering those working in sectors such as waste management the extra flexibility and dexterity they need.

“Being punctured by objects such as hypodermic or glass needles, razor blades or metal wire remains a common and very serious risk for workers, one that can even lead to viral infections such as Hepatitis A, B, or C,” says Stéphanie Quilliet, product manager EMEA for Honeywell Industrial Safety.

Picguard Urban is made using puncture and tear resistant para-aramid, polyurethane and ceramic materials that protect the palm and fingers effectively. Additionally, reinforced protective coating on the fingertips and hand side offer better abrasion and puncture resistance.

Honeywell Industrial Safety helps organisations manage workplace safety, offering a range of industrial safety products.

_________________________________________________________________________________________

Leafield reports soaring sales of cup recycling solutions

Container manufacturer Leafield Environmental has reported record sales of its cup recycling bins due to a renewed commitment of businesses to tackle disposable cup waste.

As many as 5 billion paper cups are reportedly used and disposed of each year in the UK which, due to a lack of recycling solutions, were either incinerated or sent to landfill.

For the last two years, Leafield has been working with cup recycling scheme Simply Cups, which has resulted in an expansion of its cup bin range and a dramatic increase in sales.

According to Justin Salmon, business development manager for Leafield Environmental: “Previously, we found it tough to sell cup bins because there was no recycling service in place. We knew though that our customers genuinely wanted to recycle their cups because it improves their recycling targets, avoids waste going to landfill and enhances their environmental credentials.

“Now that there is a robust scheme in operation, through Simply Cups, there is a huge incentive for them to recycle their cups, which gives us the opportunity to help them find the best bin for their needs”

_________________________________________________________________________________________

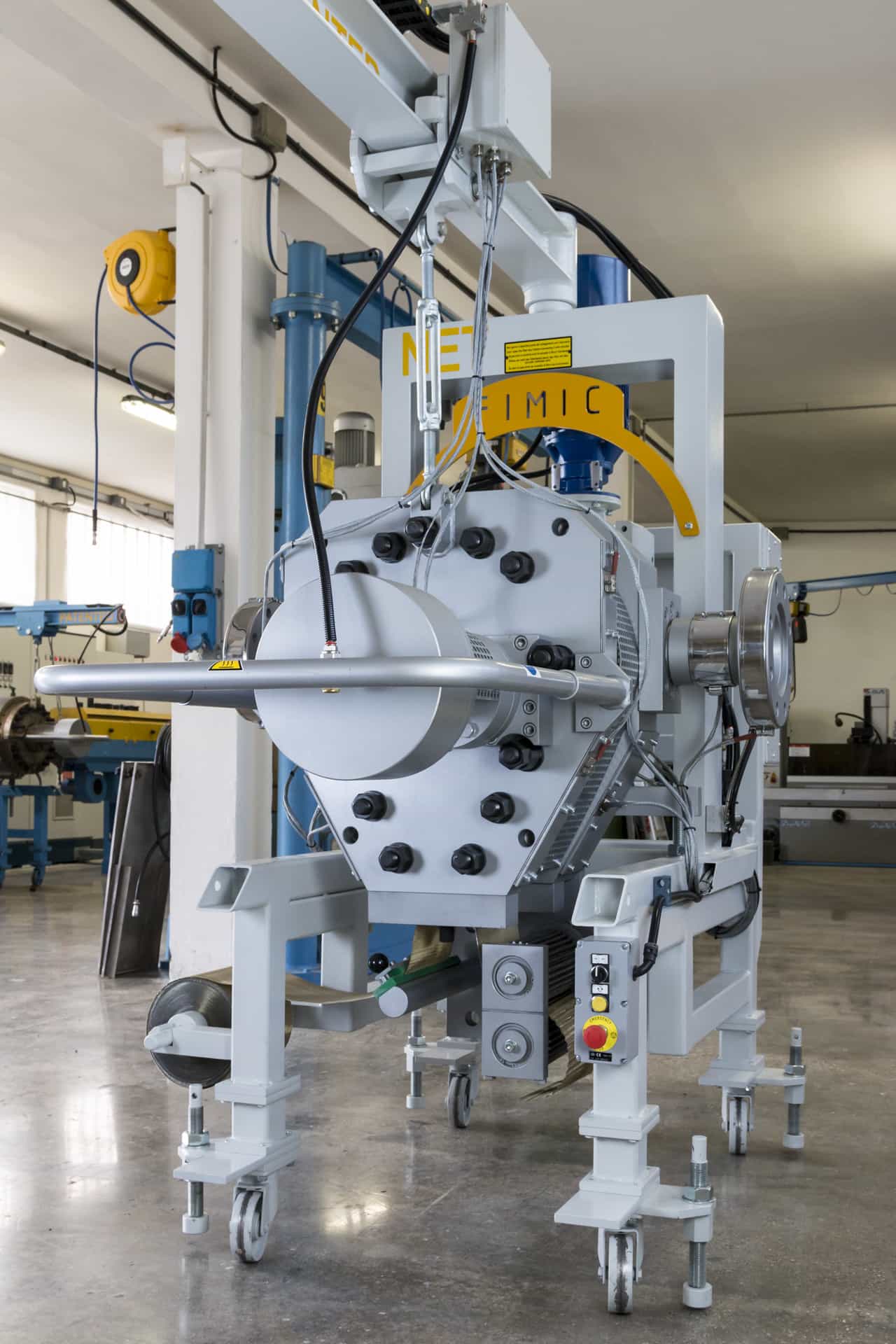

Fimic introduces new filtration technology

Fimic has introduced its latest innovation in filtration technology, with the aim of reaching a higher quality in recycled plastic pellet production.

In addition to improving its core product, the RAS model, Fimic has also added to its range of solutions, with a double filtration machine (the ERA) and belt-type model (the NET).

The RAS model built by Fimic, with its punched or laser drilled screens, was developed to manage highly contaminated materials. However, in some cases the material can be so contaminated, that the only possibility is to filter it twice to get to the high quality needed.

In order to avoid the costs of two extruders or a gear-pump and a second filter, Fimic designed a self-cleaning filter (the ERA model) that can filter twice inside a single machine containing a double filtering chamber.

Fimic now also offers its own belt solution, the NET model. This machine is a solution when material is not highly contaminated, otherwise the cost of the mesh would be too high, or when there is a high level of aluminium, to allow an automatic change of the belt.

Subscribe for free