Economic Skips grabs JCB excavator

Economic Skips has purchased the JCB JS370 tracked excavator for operation at its Mercury Way site, near Bermondsey.

The excavator was supplied by local dealer Greenshields JCB.

It is equipped with a large finger grab, allowing it to carry out the initial processing of waste at the facility. This is the first time a JCB JS370 has been used in such an application.

Chris Guinnelly, site facility manager at Economic Skips, based in New Cross, London, explained why he chose the excavator.

“The JS370 is a robust, compact and efficient machine,” he explained.

Mr Guinnelly added: “Its ability to handle with the finger grab, its good visibility and its ability to cope in a dusty environment are key features for us.”

Bobcat expands self-levelling planer attachment range

Equipment-company Bobcat has added two new model sizes to its high flow compact loaders.

The two new planer attachments, the PSL50 (50 cm width) and PSL120 (120 cm width), have been introduced to meet customer demands.

The PSL50 offers the same features as the existing PSL60 60 cm model with self-levelling, side-shift and tilting. The size of the PSL50 planer is particularly suited to the requirements of fibre optic projects.

Providing 20% more productivity through increased width, the PSL120 shares the same features as the existing PSL100 100 cm width model, with self-levelling, side-shift and tilting.

The fully hydraulic design of the self-levelling planers ensures all functions can be controlled from the operator seat.

Carl Bird Skip Hire chooses Finlay Plant

Norfolk-based skip hire company, Carl Bird Skip Hire, has chosen Finlay Plant Southern as its partner to deliver a mobile waste recovery solution to sort volumes of material on site.

Based in North Walsham, Carl Bird has worked closely with Finlay Plant Southern since 1991 and throughout that time the company has purchased four Terex Finlay machines.

Now the family-run business has teamed up with Finlay Plant Southern by introducing a Kiverco PS122 Picking Line to its site for a two-week hire period.

The machine – which is fitted with an overband magnet to recover ferrous metals – was fed with Carl Bird Skip Hire’s on-site Terex Finlay 883.

This enabled the four-man picking line team to clean up thousands of tonnes of contaminated hardcore, recovering wood and plastics, as well as clean stone.

Carl Bird, managing director of Carl Bird Skip Hire, was impressed with the performance of the machine.

“The beauty of the plant was that it was delivered in the morning and was up and running within two to three hours,” he said.

“It’s done a brilliant job. We didn’t even run it every day and it still processed a 4,000 tonne stockpile.”

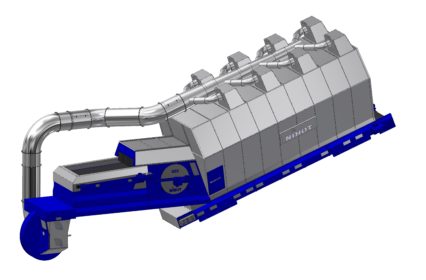

Nihot launches RDF technology

Dutch waste separation technology supplier Nihot has launched a separation solution machine which removes inert materials from the waste stream for the protection of secondary shredders.

The ‘SDX windshifter’ is designed for RDF/SRF installations as the ultimate separation solution for realizing premium protection of the secondary shredders at the lowest cost per ton.

“Nihot has many years of experience with windshifters in RDF/SRF applications,” explained Nihot’s sales and marketing director Joep Barenbrug.

He added: “With our proven SDS-type windshifter, we have numerous operational references worldwide where secondary shredders are extremely well protected by the highly efficient removal of contaminants. Our separation efficiency ensures perfect quality of RDF and SRF material.”

Alderney renews baler investment

Alderney’s states works department has contracted recycling machinery company Middleton Engineering to supply and install a new closed-end, semi-automatic baler at its Glacis recycling centre.

The machine will bale a full range of waste streams prior to shipment off the island for processing.

This is Alderney’s second baler from Middleton Engineering and a direct replacement for an earlier machine installed back in 2006 to improve the efficiency of storing and transporting waste.

The third largest and most northerly of the Channel Islands, Alderney has a resident population of around 2,400, peaking to more than 4,000 during the summer months. Like other island communities a zero-land fill policy means all waste recycling is sent off island for processing.

Currently they sort and grade between 12 and 15 tonnes of mixed recycling per week. This includes RDF and waste paper, card, plastics, cans and tyres.

Doosan to collaborate with Trimble

Doosan Construction Equipment is collaborating with Trimble to introduce a Trimble Ready factory option for Doosan excavator customers.

The Trimble Ready option will be available direct from the factory through Doosan Smart Solutions for use with Trimble GCS900 2D and 3D Grade Control Systems.

The Trimble GCS900 Grade Control System gives operators access to design surfaces, grades and alignments on a display inside the excavator cab.

It uses GNSS, GPS, laser, sonic or total station technology to accurately position the blade or bucket in real time, significantly reducing material overages and improving the contractor’s productivity and efficiency.

The collaboration between Doosan and Trimble means that customers in Europe will be able to order Trimble Ready excavators to enable a faster and simplified installation of Trimble GCS900 2D or 3D Grade Control System components with no welding, re-painting, drilling or disassembly required.

Subscribe for free