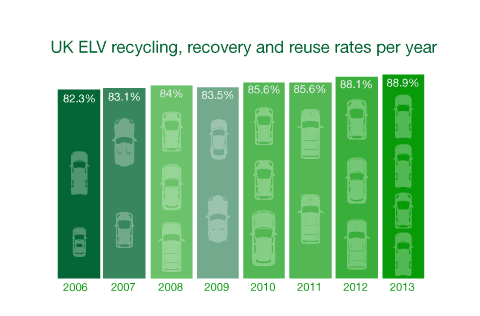

With a legal target of 95% reuse/recycling/recovery in 2015 the UK is still some way short of the goal. However, developments in the use of shredder residue and more energy recovery are expected to see the UK meeting the target by 2015 or relatively soon after.

The data is compiled by the Department for Business which has responsibility for ensuring the UK meets the requirements of the EU Directive on the reuse/recovery and reuse/recycling targets on ELVs.

The latest figures show that the number of vehicles counted in the data (cars and light commercial vehicles) was down by almost 14,000 in 2013 at 1,149,459 when compared to the 2012 figure of 1,163,123 (see letsrecycle.com story).

According to the data, most aspects of the process were relatively similar year on year. However, there was an increase in the reuse of materials from the car dismantling process and depollution in a sector categorised as “other materials arising from dismantling”.

The Department for Business reports that all businesses treating ELVs, whether the vehicles are within the scope of the Directive or not, have to be permitted as an Authorised Treatment Facility (ATF). This means that sites handling Heavy Goods Vehicles or motorbikes have to work to the same standards as cars, although the reporting is not under the Directive.

Fluids

One problem area highlighted by BIS is that of fluids. In a report accompanying the data, the Department explains: “There are a number of difficulties here, both related to when the vehicle was actually received, when depollution occurs, storage of fluids which may be in large or small containers, and subsequent collection of the fluids for treatment by specialised recycling companies. Reporting periods are frequently crossed, and with significant numbers of ATFs only handling quite limited numbers of vehicles in the UK, it can be a number of years before it is economic for fluids to be collected meaning that fluids recycling can appear to be zero one year and unfeasibly high the next.”

The Department then suggests that the EU considers introducing a protocol weight amount for fluids to resolve data issues, as already happens with fuels.

The metal content of cars – ferrous and non-ferrous – in the UK have traditionally been based on research work by the metals recycling sector with the support of BIS resulting in a 75% metal content. However, BIS now says that more metal is being collected from the shredder process and the overall metals figure has been increased to show this

Since the trial was conducted, a number of shredders have installed new equipment and technology which improves the metallic gain from that showed by the UK assumption. Since the nature of these shredder investments is commercially sensitive, detailed supporting information is not provided here, but the overall metallic recovery figure shows a small increase beyond that of the shredder trial to reflect these increased efficiencies.” And, BIS remarks that: “The UK authorities have visited the shredder sites in question to examine these new processes.”

Chas Ambrose, secretary of the Motor Vehicle Dismantlers Association, commenting on the increased recycling and recovery rate, said: “Generally this is an encouraging move upwards showing a steady rise. Making the 95% rate will be very challenging in many ways including technologically and we would not expect it to be reached in the next year or so. It would be reached as part of a steady progression in a few years’ time.”

Mr Ambrose added: “Much will depend on the work of the shredders and we support their continuing investment in their processing and other technologies.”

SMMT

On the car manufacturing side, the Society of Motor Manufacturers and Traders last week highlighted “how considerable investment has been necessary in new processes” to meet the 95% target.”

The SMMT said: “The Innovative Environmental Solutions site at Oldbury has new processes to recover more materials from the ELVs, then uses a pyrolysis plant to turn the residual into electricity. The 40MW facility will divert over 500,000 tonnes of waste from landfill”.

The Oldbury plant is situated next door to a shredder run by European Metal Recycling (EMR) and will take shredder residue from the plant and from other EMR shredders for incineration with energy recovery.

The SMMT also highlighted the development of a Shredder Waste Advanced Processing Plant in Manchester which “is also delivering enhanced separation of the constituents of a vehicle, to enable better recycling and energy streams.” The plant is run by Axion Polymers and also involves metals recycling firm S. Norton.

Subscribe for free