The facility will process up to 75,000 tonnes of material each year under a 23-year contract with waste management firm Cleanaway. Under a partnership between Greenwich council and Cleanaway, the plant has received 1.5 million in funding from the London Recycling Fund.

Environment secretary Margaret Beckett starts the new recycling plant in Greenwich, accompanied by Cleanaway CEO Jean-Louis Laurent (left) and Greenwich council leader Chris Roberts |

Opening the facility, Mrs Beckett said: “London faces a considerable challenge to change the way it deals with its waste. The opening of this facility today does not take away the challenge but it does provide significant help in developing a world class solution that people in Greenwich rightly demand.

“I am hugely encouraged to see the partnership working so effectively together to provide the major investment in recycling that is needed at this critical time,” Mrs Beckett said.

Cleanaway has brought technology from all over the world for use in the MRF, which will separate paper, cardboard, cans, glass and plastic bottles collected in commingled kerbside collections in Greenwich.

Greenwich is currently providing recycling collections for 46% of households and 36% of flats, with plans for expansion borough-wide. The council believes it is now recycling about 17.4% of its household waste, up from 12% in 2003/04.

Regeneration

As well as taking in material from households in Greenwich, the new MRF will have capacity available for other London boroughs. It could also be important in servicing the expanding population as regeneration gets under way in the Thames Gateway, according to Greenwich council leader Chris Roberts.

”The opening of this facility today does not take away the challenge but it does provide significant help.“

– Margaret Beckett

Cllr Roberts said: “This will catapault us, it is a big boost towards recycling in Greenwich. With this facility in operation, we will be able to sell our landfill allowances. There's also capacity to accommodate all the regeneration in Greenwich and the Thames Gateway.”

Technology

Cleanaway has worked with engineering firm OKLM to build the plant, using equipment including a trommel, screens, ballistic, magnetic and eddy current separators as well as air cascade separation systems.

Speaking to letsrecycle.com, the chief executive of Cleanaway, Jean-Louis Laurent, said that the company had been able to use its knowledge from operating in countries including Australia, Germany, Norway and the UK in designing and building the Greenwich plant.

Equipment has been provided by companies including West Midlands firm General Kinematics, and the plant includes the TiTech Polysort optical separation system, which uses infra-red light to distinguish between two types of plastic bottles – PET and HDPE.

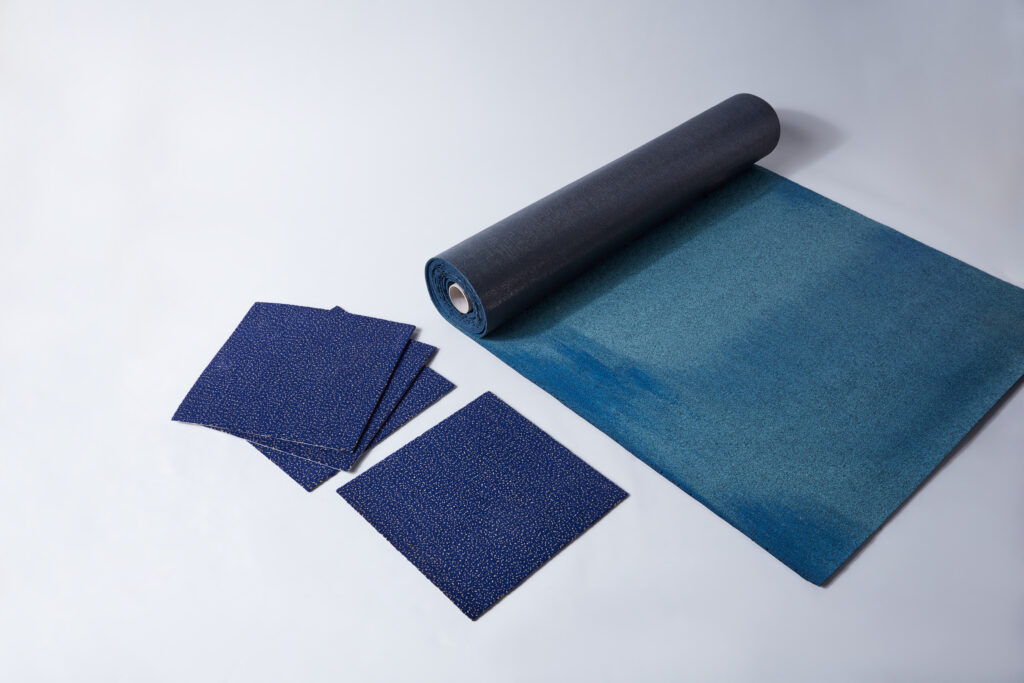

The new recycling plant at Greenwich uses technology from across the globe |

Education

But, while the equipment was “state-of-the-art”, Mr Laurent said key to its operation would be educating residents to keep contamination levels as low as possible.

Mr Laurent explained: “One element that is critical to the performance of such a plant is the quality of the waste we get coming in. That depends on the education of the people. That is why we are working together with the council to provide education for kids and adults to make sure they separate their putrescibles from the recycling.”

Under the contract with the council, the plant must recycle at least 95% of the material it processes, and the plant is currently achieving a 98% rate, Cleanaway believes.

| Related links: |

Cleanaway's development director Andrew Garcia said the material sorted in the MRF would go to reprocessors in long-term and short term arrangements, with some material being exported “to recognised reprocessors”. Mixed glass from the MRF would be going to make new aggregates, but was available for container reprocessors if there was demand.

Subscribe for free