The two plants will feed a combined 800 Nm3/h of biomethane into the local gas grid and are the first UGS systems of their kind.

UGS has said that the projects were “particularly challenging” as a result of a “change in operating procedures and the high grid requirements”.

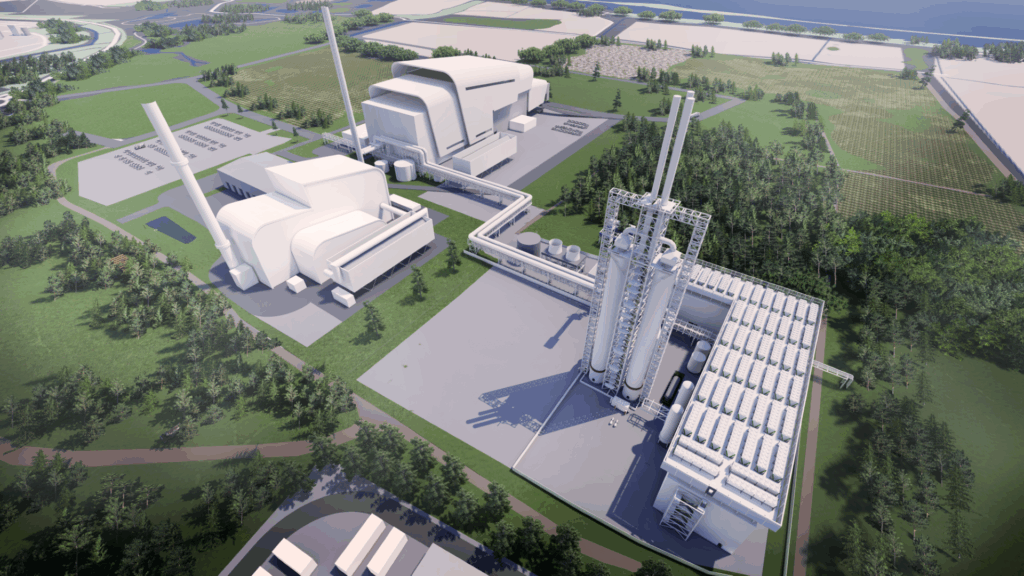

Site specifics

The two sites are located at the Three Petals RNG plant in Berlin, Wisconsin, and the Red Leaf RNG plant at the Maple Row Dairy Farm in Saranac, Michigan.

They both process H2S concentrations of more than 4,000 ppm, which are sent directly into the compressor of the gas treatment plant and then directly through the first membrane stage.

The result is almost pure biomethane in natural gas quality with only a residual H2S content.

Project developer Novilla RNG and UGS opted to use a multi-stage, membrane-based treatment process that tolerates very high H2S concentrations of up to 30,000 ppm.

Bypassing biogas pre-treatment

Both sites chose to bypass the pre-treatment of the biogas and the installation of additional desulphurisation systems.

UGS said that when high H2S concentrations occur, operators normally have to pre-treat the biogas with additives or install an expensive external desulphurisation system for the entire biogas volume. This reduces the H2S load to levels that can be handled by an activated carbon filter.

However, this often results in the need for such systems to increase oxygen addition which can affect the quality of the gas produced and can also be costly.

Mark Hill, co-CEO of Novilla RNG commented: “Remarkably, the desulphurisation via the membrane unit itself, followed by the fine desulphurisation on the product gas side, means that the grid specifications can sometimes even be met without using the De-Oxo system. However, the DeOxo system offers absolute safety for all our sites.”

Subscribe for free