Shotton has previously been home to a machine producing newsprint but was sold last year to Turkish paper giant Eren, which is to install a state-of-the-art machine to make cardboard.

The new machine will add more competition to the UK market in which DS Smith, SAICA, and Smurfit Kappa currently have the largest other cardboard making machines.

The SAICA machine in Partington, Manchester was opened in 2012 while Smurfit Kappa’s most recent machine was at Townsend Hook, Snodland, Kent in 2016. DS Smith is understood to be in the process of preparing plans for a new paper machine at its mill in Kemsley, Kent although details have not yet been released or confirmed.

Family-run

Valmet announced yesterday (May 4) that is to supply Eren Paper at Shotton. Established in 1969, Eren Holdings is a family run conglomerate headquartered in Istanbul, Turkey. It has business interests in paper, packaging, cement, energy, retail and port operations.

Eren explained that Modern Karton, its paper manufacturing subsidiary, is “an expert in producing paper and packaging by using 100% recycled fibres. Within its paper factory in Turkey, 1.2 million tonnes of paper are produced annually, making it the largest paper manufacturer in Turkey and one of the top 10 paper companies in Europe. Eren Paper’s Shotton Mill Limited is part of Eren Holding.”

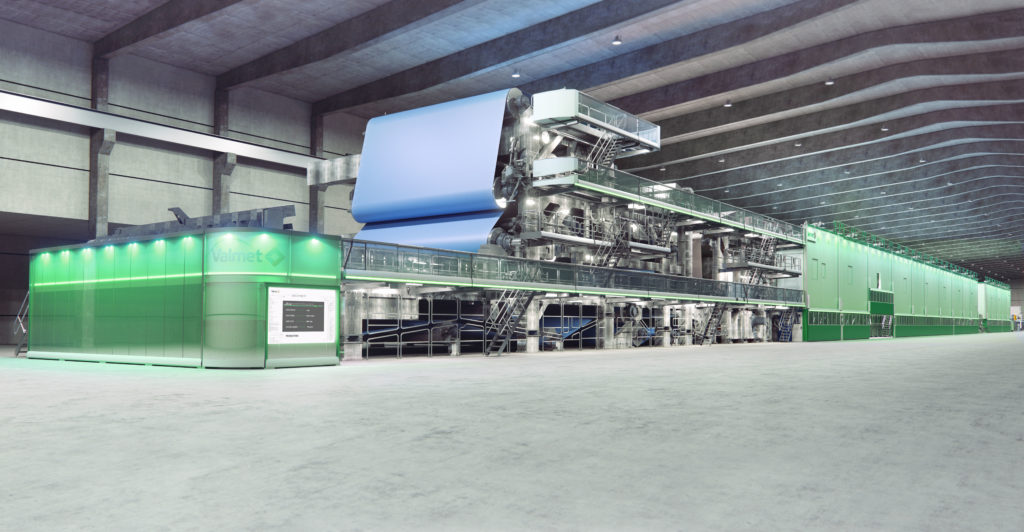

Valmet said it will supply lines, largely automated, to handle OCC, stock preparation and container board lines, “industrial internet solutions and services to Eren Paper’s Shotton Mill Limited in the United Kingdom. The new container board making line (PM3) will produce high-quality testliner and fluting grades, and it will use 100% recycled paper. The start-up of PM3 is scheduled for the second quarter of 2024.”

Value

Value of the Shotton order has not been disclosed but a project of this size and scope is typically valued at around 150–170 million Euros.

“Shotton’s new container board machine will make our paper mill the largest and most technologically advanced paper mill in the UK. We chose a board making line with high performance, high speed, and higher production rates”, said Hamdullah Eren, chairman of the board at Eren Paper/Modern Karton.

Shotton’s new container board machine will make our paper mill the largest and most technologically advanced paper mill in the UK

“Our technical highlights together with the speed and production potential of the container board machine were definitely the decisive factors to Eren Paper. Valmet’s OptiAir impingement dryer will give substantially higher runnability, and a hard nip sizer will increase the strength properties of the produced board. All these arguments were supported by the results from the references we presented to Eren Paper. Additionally, the OCC line will be the largest one delivered by Valmet,” said Mika Ollikainen, vice president, sales and marketing, Valmet.

Valmet’s delivery, the company explained, “will include a new OCC line with reject handling, stock preparation, and approach flow system, and a high-speed container board machine. The OCC line is featured with an extensive product portfolio of the latest technology for extreme cleanliness and strength. It is equipped with two bale handling systems; two vertical pulping stations; HC, LC and reverse cleaning; coarse screening, fractionation, and LF screening; LF dispersion; and SF and LF refining technology.”

Performance agreement

The start-up and further optimization of the new board machine will be supported with a Performance Agreement in cooperation with Shotton Mill to support the continuum of the successful start-up curve, Valmet said. It noted that: “Additionally, the production will be supported remotely from Valmet Performance Center. Industrial Internet solutions, such as advanced monitoring and predictive applications, will complete the optimisation of the paper machine operation. Valmet paper machine clothing, spare parts and consumables packages will be delivered as well.”

The board machine with a 10,110-mm-wide fabric will produce testliner and fluting grades with a basis weight range of 70–135 g/m2. The design speed of the machine will be 1,700 m/min and the annual capacity approximately 650,000 tonnes.

Subscribe for free