Ward invests in crane at Redcar metals site

Derbyshire-based Ward has invested £800,000 in a Mantsinen 70 hydraulic crane at its metal processing site in Redcar to increase its export handling capacity for ferrous metals.

The heavy-duty crane has a maximum reach of 24 metres, weighs 95 tonnes, and can lift up to 15 tonnes of material in each movement.

Thomas Ward, commercial director at Ward, said: “This is the largest piece of equipment in our business to date for bulk handling of scrap metal.

“The new Mantsinen 70 hydraulic crane is more energy efficient, helping to reduce both our handling costs and CO2 emissions per tonne at our Redcar site.

“It also has the benefit of helping to increase loading speeds, which is important factor when loading for our end users.”

Ward bought the crane through Cooper Handling, the exclusive UK distributor of Mantsinen hydraulic cranes, in early 2021 and took delivery in December.

With a turnover in excess of £200 million, Ward operates six sites in the East Midlands and four other locations between London and Middlesbrough.

REP-TEC’s latest balers named after ‘iconic’ cranes

Northern Irish equipment manufacturer REP-TEC has launched two fully automatic balers named after Belfast’s “iconic” cranes.

Designed and manufactured at REP-TEC’s production facilities in Northern Ireland, the Samson and Goliath balers are intended for companies who bale a range of material from cardboard, plastics, and steel and aluminium cans to refuse derived fuel.

Colm Grimes founded REP-TEC in 2020 and is currently the company’s CEO.

He said: “We are delighted to launch our two new fully automatic balers, Samson and Goliath, named after Belfast’s iconic cranes.

“And, as the names suggest, we want them to stand tall in the industry and do the heavy lifting in recycling MRFs.

“We are also very proud to design and manufacture machines in Northern Ireland and like so many local companies we have the belief that we can be the best in the world at what we do.”

Whitham Mills supplies Haulaway with ‘huge’ twin ram baler

Sussex-based waste management company Haulaway has invested in a “huge” 20 tonne per hour Godswill twin ram baler from recycling equipment manufacturer Whitham Mills.

Haulaway will use the GB-1111TR to bale hard and soft plastics, OCC, and paper at the company’s newly opened site in Polegate East Sussex.

Steve Walton, Haulaway’s manager, says it was the “thickness of steel, quality of build and stellar reputation” that convinced him to purchase the machine.

Mr Walton said: “We took the task of insuring that the right machine for the right job was addressed properly and with high quality equipment such as the Whitham Mills-Godswill twin ram you need the highest quality and assurance of reliability that this equipment and the team has.

“Whitham Mills are the market leaders in both, and the support of the team was paramount in our decision process to award Whitham Mills the order.”

Haulaway’s Polegate site that has been designed to receive bulky mixed plastics from household waste recycling centres, transfer stations, and independent waste companies, as well as commercial dry mixed recycling and cardboard.

Whitham Mills holds exclusive distribution rights for Godswill balers in Europe.

Warwick Ward becomes Terex Recycling Systems distributor

Plant manufacturer Terex has welcomed recycling equipment supplier Warwick Ward as the “latest” UK distributor of its range of stationary and modular recycling systems.

Launched in 2021, Terex Recycling Systems specialises in the design and build of stationary and modular recycling systems.

Its product line-up includes shredders, feeders, conveyors, screeners, sorters, and separators.

Warwick Ward has already worked in partnership with Terex’s wood processing, biomass, and recycling equipment manufacturing arm, Terex Ecotec, for the past seven years.

Mark McGlinn, recycling equipment division manager at Warwick Ward, said: “We are delighted to agree the dealership for TRS. Terex Recycling Systems will further strengthen our recycling product portfolio, allowing us to now offer both mobile and static recycling solutions to our customer base.

“The TRS modular design offers great flexibility for customers to either add a new piece of equipment into an existing processing line or provide the complete solution for a static waste or wood processing plant.”

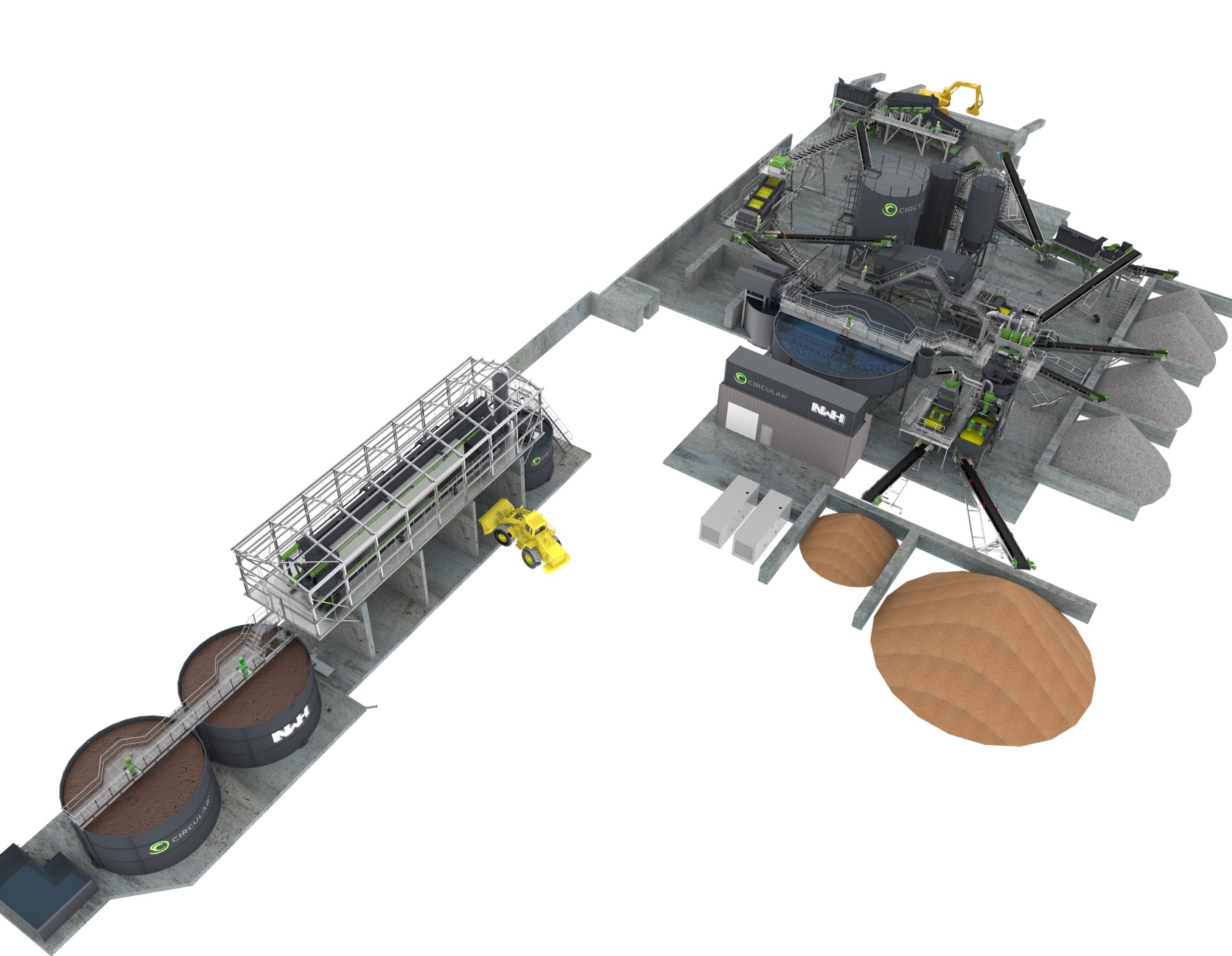

NWH breaks ground for £4.4m Edinburgh wash plant

The Midlothian-based NWH Group has broken ground at the site of its construction and demolition waste recycling wash plant on the outskirts of Edinburgh.

The company says the £4.4m investment at its Mayfield site will enable the recycling of inert construction and demolition wastes through washing, screening, crushing, and water treatment equipment.

The equipment will be installed around existing plant operations to minimise downtime and will be fully operational by May 2022.

Mark Williams, CEO at the NWH Group, said: “As we continue to increase our contribution to the circular economy, and in turn become even more sustainable as a business, our latest investment facilitates an increase in our production of recycled resources.

“This not only improves our product offering to customers, but also further reduces waste to landfill.

“By promoting the use of recycled aggregates, we’re helping reduce the levels of primary production to preserve the depleting natural reserves.”

The NWH Group says the plant will increase its processing capabilities from 75 to 250 tonnes per hour.

It will also expand the company’s product range to include 10mm aggregate, 20mm aggregate, 40mm aggregate, type 1 aggregate, washed concrete sand, and ultra-fine sand.

Subscribe for free