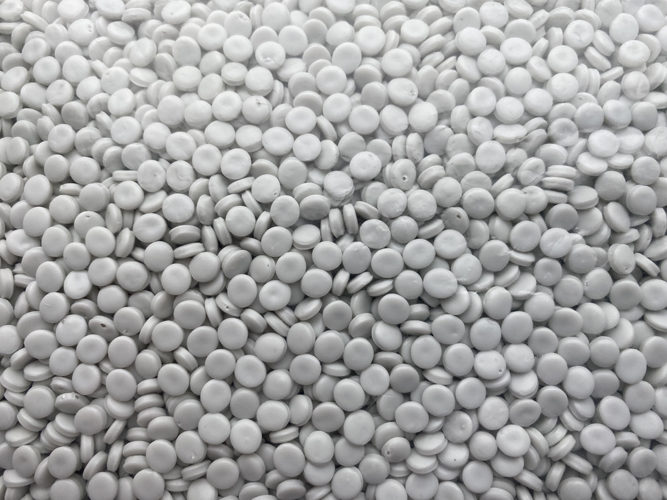

Berry has also announced that recycled plastic pellets it produces through its CleanStream process in the United States can now be used in food contact products and the process will be used at Leamington Spa.

Plasgran is a longstanding UK recycling business which was established in 1999 and acquired by the US plastic recycling giant Berry in 2019.

Consumer goods

Berry said that the renaming “reflects Berry’s leadership in recycling and the development and securing of circular polymers. This will support the move towards a circular and net zero economy, for which Berry has already targeted achieving 30% circular plastic use across its fast-moving consumer goods packaging by 2030.”

Plasgran is one of the UK’s major recyclers of rigid plastics. Among its feedstock is local authority-sourced material including source segregated PP pots, tubs and trays and bottles from materials recycling facilities (MRFs) and plastic recycling facilities (PRFs) as well as some HDPE. The company does not deal in PET products.

The Leamington Spa facility will make use of Berry’s CleanStream technology, described as “the world’s first closed-loop system to mechanically process domestically recovered household waste polypropylene (PP) back into food-grade packaging.”

CleanStream, the company explained, has recently been granted a ‘Letter of No Objection’ from the US Food & Drug Administration (FDA). This means that the post-consumer recycled PP produced by the process can be used in levels up to 100% recycled content for food contact applications.

Food grade

This use of recycled plastic in food grade material is seen as important as there will be strong demand from the food and supermarket sector for recycled plastic which can be used in food containers, driven partly in the UK by the plastic packaging tax. Much of the plastic recycled to date has gone into lower value products and items such as plastic benches.

Berry is now to seek similar food authority approvals for its material in Europe.

Rigid

“The launch of Berry Circular Polymers brings together our advanced rigid plastics recycling facilities,” said managing director Jeremy Blake. “Our technical expertise and experience will enable us to deliver recycled material of high quality and consistency to support our customers’ drive for sustainable solutions.”

Together with its UK film recycling facilities in: Dumfries, Scotland; Heanor, Derbsyhire; Rhymney, Wales and on the continent in Steinfeld, Germany, Berry says it is now one of the largest plastics recyclers in Europe, with the ability to handle around 200,000 tonnes of material annually.

Subscribe for free