Their company, Nulife Glass Ltd, is based at Stourbridge and is now ready to start selling the furnaces suitable for processing the glass from up to 1,000 CRTs a day.

Mr Greer told letsrecycle.com the process can recover more than 95% of the lead within crushed glass from the cathode ray tubes from television sets and computer monitors.

The lead content in CRT glass can be as high as 20%, with a single 34-inch television containing as much as a kilogramme of the metal in oxide form. Mr Greer explained that 10 years of research had gone into the furnace, which had seen him visiting lead crystal glassmakers in Ireland to see how lead it put into their glass, after which he had sought to reverse the process.

“This is the Holy Grail of recycling, because no one has ever worked out how to get the lead out,” he claimed. “It's been a long journey, but it's working far better than we ever thought it would.”

Much of the leaded glass currently reclaimed from old CRTs in the UK, under the new producer responsibility regulations (see letsrecycle.com story), is being exported to be made into new CRTs. But Mr Greer said that a decline in sales of CRT televisions and monitors, as new technologies like LCD and plasma screens rise in popularity, meant the CRT market for old CRT glass was likely to decline in the long-term.

Products

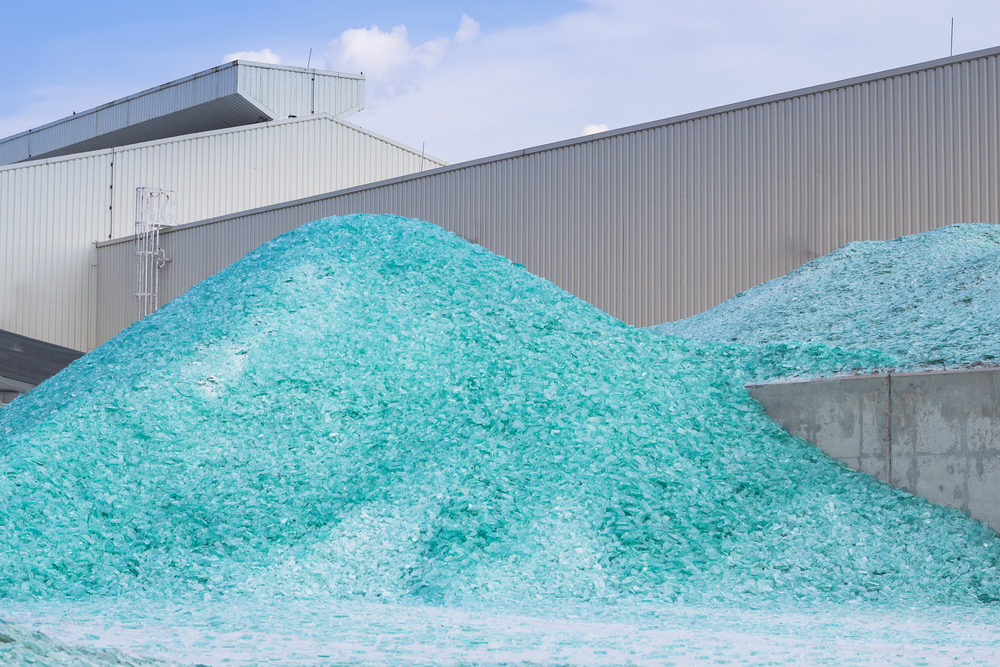

Mr Greer said the lead from the Nulife process could be sold onto the global lead market, while the glass was suitable for use in making fibreglass insulation, aggregates or tiles. Around two tonnes of material a day is being processed at the Stourbridge site, but the company is yet to ship out its glass end product.

The company has already had some interest in its furnace technology from “several UK recyclers” as well as firms in Europe and the States.

Subscribe for free