Pow meets MP over Leicestershire MRF concerns

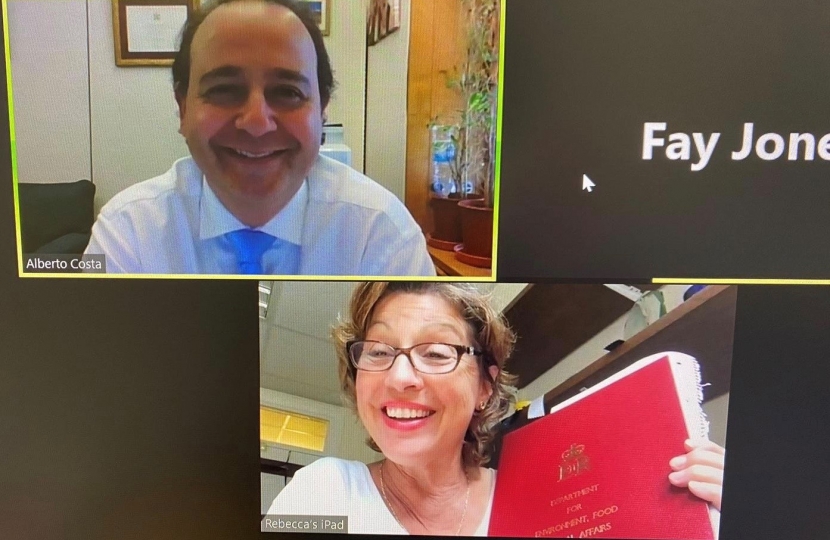

The MP for South Leicestershire met with recycling minister Rebecca Pow last month to discuss concerns about a proposed materials recycling facility (MRF) in Shawell, Leicestershire.

The Cotesbach mechanical biological treatment (MBT) facility in Shawell Quarry, around five miles north of Rugby, has been closed since 2016. In April, site owner Tarmac Trading and international waste management firm Beauparc Group put forward proposals to repurpose the facility into a MRF with an annual capacity of 150,000 tonnes.

The facility would import and process household, commercial and industrial waste from across the UK and Ireland.

Describing the facility as “deeply troubling”, Alberto Costa MP expressed concerns about a potential increase in HGVs entering the village and the environmental impact of importing waste to South Leicestershire.

Mr Costa said: “Following my raising this matter with the Prime Minister at the end of June, I was very pleased to meet with the Defra Parliamentary Under Secretary of State to again reiterate the very understandable concerns of my constituents in Shawell toward these plans.

“This was a very useful discussion with the Environment Minister about the UK’s wider waste plans, and how appropriately placed recycling centres can fit into this from a local perspective.”

Machinex celebrates record year for baler sales

Canadian machinery manufacturer Machinex says it has had a record year for the sale of balers in Canada and the United States.

The company says it sold eight single ram and 12 II ram high capacity balers.

In North America, II ram and single ram balers were installed for long-time customers such as Rumpke Recycling in Louisville and Medina and Republic Services in Greensboro. In Canada, balers were installed at GFL facilities in Richmond and Winnipeg.

Rusty Angel, Eastern region sales manager in the United States, said: “One of our clients in St Louis considered four other major II ram baler manufacturers as a part of their buying process.

“They selected the Machinex baler because we had the lowest ‘cost of ownership’ over a 10-year period when considering baling capacity and annual maintenance.”

Designed to meet the multi-purpose needs of recyclers, Machinex says its baler series maximises density while reducing operating costs.

MacRebur and KEENAN team up to produce plastic roads

Plastic road company MacRebur has teamed up with Irish machinery manufacturer Keenan to produce sustainable road surfaces using mixed waste plastic.

Though typically used within the dairy and beef sectors, when equipped with a KEENAN controller and InTouch technology Keenan’s MechFiber300 diet feeder can be used to mix granulated plastic waste. This mix is then distributed to asphalt producers.

One tonne of MacRebur mix contains the equivalent of 80,000 plastic bottles, Keenan says, and the Scotland-based business aims to work with local authorities to use their waste to build roads.

Gordon Reid, co-founder of MacRebur, said: “Quality and reliability are extremely important to us — we can’t have any variability in our batches, so we need to make sure our product is consistent. This is a key factor for using Keenan’s machinery.

“Additionally, the Keenan controller enables us to use exactly the right amount of activator to create the correct blend.”

MacRebur uses plastic waste destined for landfills or incineration and adds it to asphalt ready for road construction and surfacing.

Monks Contractors wins Lancashire fleet contract

Lancashire county council has awarded plant and machinery hire firm Monks Contractors a five-year contract to deliver fleet hire and maintenance services.

The new contract will see Monks Contractors provide 30 new Volvo tractor units and BMI waste trailers to Lancashire Renewables Ltd, to be used to transport municipal and recyclable waste on behalf of the local authority.

Monks Contractors’ managing director Chris Monk said: “It’s fantastic Lancashire county council has chosen a local partner to deliver this ambitious project and we can’t wait to get started.

“Our company motto is ‘working towards a greener environment’, so Lancashire Renewables’ sustainability objectives align perfectly with our own.”

Lancashire Renewables was established for the operation and management of two central waste treatment facilities built for the Lancashire Waste Contract.

Paul Brindle, general manager at Lancashire Renewables Limited, said: “We are keen to continue to build and strengthen our relationship with Monks over the duration of the contact, and have confidence that the services provided will support in the delivery of our objectives and the management and haulage of waste, for the people of Lancashire over the next five years.”

The contract begins today (1 September).

Subscribe for free