This was the message on scrap quality to delegates at last week’s IARC Automobile Recycling Congress in Berlin. The event also heard from Artemis Hatzi-Hull, EU Commission DG Environment who has responsibility for the EU’s end of life vehicle regime.

The call for improvement in material quality came from the UK’s Professor Julian Allwood from the University of Cambridge who argued that the “European steel industry is facing disaster because they don’t realise they need to make steel from scrap”.

Professor Allwood reasoned that “there would be big gains if we could make new vehicles from scrap if we could get the copper out.”

His argument centres on the fact that most steel scrap contains other metals, notably copper, and is generally used by steelmakers to make construction products, such as reinforcing bar, which don’t require high quality steel. And, he pointed out that “we already have all the primary production capacity we will ever need”.

Professor Allwood said that for a true circular economy, “assuming we have a global excess supply of steel for reinforcing bar, we could take scrap steel back for making cars and mining of half of the iron ore we mine each year could be avoided. Making steel by electric arc furnace route generates half a tonne of carbon compared to 1.3 tonnes produced for each tonne of steel made from iron ore.”

The top EU official with responsibility for the Directive on end-of-life vehicles, Artemis Hatzi-Hull, was in celebratory mood at the conference.

She said that she had every reason to be happy as the Directive was celebrating its 15th year and had largely been successful but she would not be drawn on whether car manufacturers were doing enough in terms of using recycled materials in car production which is one of the aims of the Directive.

Mrs Hatzi-Hull reminded delegates that as from 2015, there was a minimum reuse and recovery target for ELVs of 95% with a minimum reuse and recycling target of 85%.

She highlighted a host of achievements of the ELV Directive including that it had been transposed to all EU Member States and that there were “no more” abandoned ELVs.

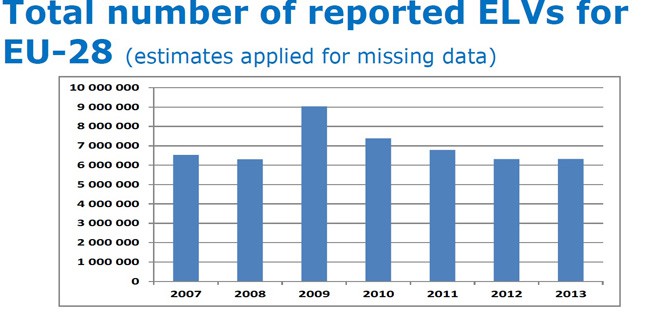

The official also noted that there had been an increase in the number of Authorised Treatment Facilities and an increase in the number of ELVs treated.

Missing

But, challenges remained, she said. There was a “systemic problem with statistically missing ELVs” and there are also problems with a lack of good quality data.

She noted that “by and large the member states do deliver” although one member state had failed to reach the target in 2013 and four had not reported their recycling rates. Action was being taken, Mrs Hatzi Hull emphasized.

And, at the front end in terms of car design, she said challenges remained. “We are working with the people in other DG units to see how we can address this, with design for disassembly, manufacturing, recycling and reuse.

The UK has its very own end-of-life metal recycling event taking place from 13-14 July 2016. More details at: www.cars-expo.com It will include practical sessions and working demonstrations.

Organised by

letsrecycle.com

And, she noted that there was also a problem in the effectiveness of recycling infrastructure which was threatened by environmental crime. “The biggest problem is getting the police to recognise environmental crime. We are in touch with Europol and Interpol.” But, Mrs Hatzi-Hull went on to praise France for its work on cracking down on illegal sites.

Competition

At a press conference during the event, Dr Tobias Bahr, Environmental Policy Director at the European Automobile Manufacturers’ Association (ACEA), clearly stated that the automotive industry has already embedded the concept of the circular economy in product development, manufacturing and an array of newly offered services. “Strong international competition automatically leads to resources being used in the most efficient way,” he pointed out.

Dr Bahr spoke in favour of an integrated approach that embraces the entire life cycle, which is preferable to an isolated consideration of resource-efficient aspects at the end of a product’s useful life. In most cases, the use phase of a vehicle is predominant and accounts for around 80% of its ecological footprint. The use phase has the greatest impact on the amount of carbon emissions a vehicle produces and its consumption of fossil fuel resources. By contrast, the environmental impact at the end of a product’s life cycle only accounts for around one per cent.

Exports

Dr Kay Oppat, Chief Operations Officer (COO) of the Germany-based metal recycling company Scholz, saw a need for action. He claimed that there are still too many end-of-life vehicles being exported, the whereabouts of which are unknown, he said at the press conference. “The recycling industry is therefore losing out on large amounts of raw materials. For this reason, new approaches are needed to improve the registration of end-of-life vehicles in Europe.”

The next IARC will be held from March 22 – 24, 2017 again in Berlin.

UK Event

In July, from 13-14 letsrecycle.com will be hosting an essential to visit car and metal recycling event at Donington Park race circuit near Derby. For further information, please visit: www.cars-expo.com.

Subscribe for free