The demand was made by Sustainable Aviation (SA), an alliance of the UK’s airlines, airports, aerospace manufacturers, air navigation service providers and SAF producers. SAF is a replacement for fossil jet fuel, derived from a variety of feedstocks, including waste.

In order for the government to hit its own target of 10% of UK aviation fuel to be SAF, the alliance made a number of demands.

This includes introducing a price support mechanism, such as that seen for biomass plants, where operators would receive a rebate per tonne of SAF created.

And, the SA has called for a strategy by Government to ensure that the needs of aviation for waste feedstocks and renewable energy are considered as part of the economy-wide net zero push. “Without such action, feedstocks could be diverted elsewhere preventing the future production of SAF,” the group said.

Call

The call comes on the back of analysis published by ICF, an aviation sustainability consultancy.

The analysis showed that the UK SAF industry has sufficient feedstocks to meet the 10% UK SAF target by 2030 domestically, but this will “count for nothing if plants are not built in sufficient numbers, quickly”.

It also highlighted that reliance on imports of SAF “would face stiff competition” in the face of global demand from EU mandates as well as targets being set in the US, Japan, Turkey, Canada, Australia and others.

“Without more urgent action from the UK Government to help unlock private investment, we risk missing out on this opportunity to build a world-leading industry here at home,” the alliance added.

Progress

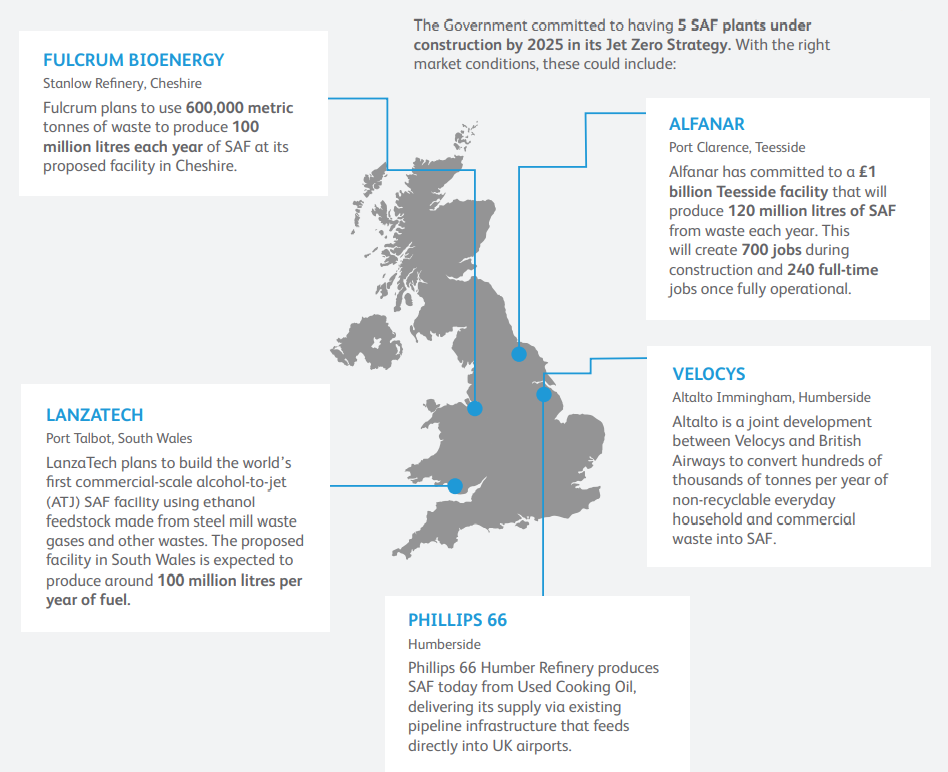

The government committed to having five SAF plants under construction by 2025 in its ‘jet zero strategy’, which involved a £165 million ‘advanced fuel fund’.

These could include Fulcrum Bioenergy facility in Cheshire, planned to produce 100 million litres of SAF annually from 600,000 metric tonnes of waste. And, LanzaTech’s planned facility in South Wales is set to produce SAF using ethanol feedstock made from steel mill waste gases and other wastes.

Other proposed projects are Phillips 66, which has plans for SAF production from used cooking oil, delivering its supply via existing infrastructure feeding directly into the UK airports. Another project will see Velocys partner with British Airways to convert residual household and commercial waste into SAF. Additionally, Alfanar has committed to a £1 billion Teesside facility that is set to produce 120 million litres of SAF from waste each year, the analysis said.

‘Final pieces’

Commenting on the development, SA chair Matt Gorman, said: “Working in partnership with Government we have seen significant strides taken towards delivering a UK SAF industry. The UK is on the cusp of something special but we need the final pieces of the puzzle in place, with new SAF capacity built and delivering SAF this decade.”

Shai Weiss, CEO, Virgin Atlantic, added: “SAF production in the UK is falling behind other countries. The government needs to think about SAF the way it thinks about offshore wind, nuclear or hydrogen in order to support aviation energy transition, create energy independence, and promote sustainable jobs.

“With the right conditions to drive investment and production at scale, SAF represents the solution for medium and long-haul decarbonisation for decades to come.”

Subscribe for free