Speaking at the annual LARAC, local authority recycling officers’ conference, Dr Ioannis Hatzopoulos, senior manager of sustainability communications at P&G, outlined the company’s investment in technology to recycle disposable nappies and other absorbent hygiene products (AHPs).

And, he signalled that the company was interested in the UK being home to its third plant. One has been built in Italy with Italian pharmaceutical business Angelini and waste company Fater at Treviso, Italy and a second plant is to be developed alongside the AEB energy from waste plant in Amsterdam.

The move is part of the company’s larger plans to provide “Europe-wide coverage” of recycling used nappies, said Dr Hatzopoulos, who proceeded to reach out to the LARAC audience to gauge their interest of a plant in the UK.

(above) Video interview by Hera Lorandos with Dr Ioannis Hatzopoulos of P&G

“We have the right technology and I’m hoping some of you will want to speak to me to see what we can do together,” Dr Hatzopoulos said to the audience.

According to statistics from WRAP, the UK disposes of around 3 billion disposable nappies a year, representing an estimated 2% to 3% of all household waste.

This is not the first time a company has attempted to set up a nappy recycling plant. Earlier this year, Canadian owned company Knowaste announced it was exploring options to build the UK’s only dedicated nappy recycling facility to the east of London after it was rejected to set up the plant in Hayes, West London, due to the impact of odour on the surrounding area (see letsrecycle.com. story).

Italy

Dr Hatzopoulos explained that the recycling plant in Treviso can process 10,000 tonnes of waste a year which is the equivalent to the AHP typically arising from a population of 1 million people.

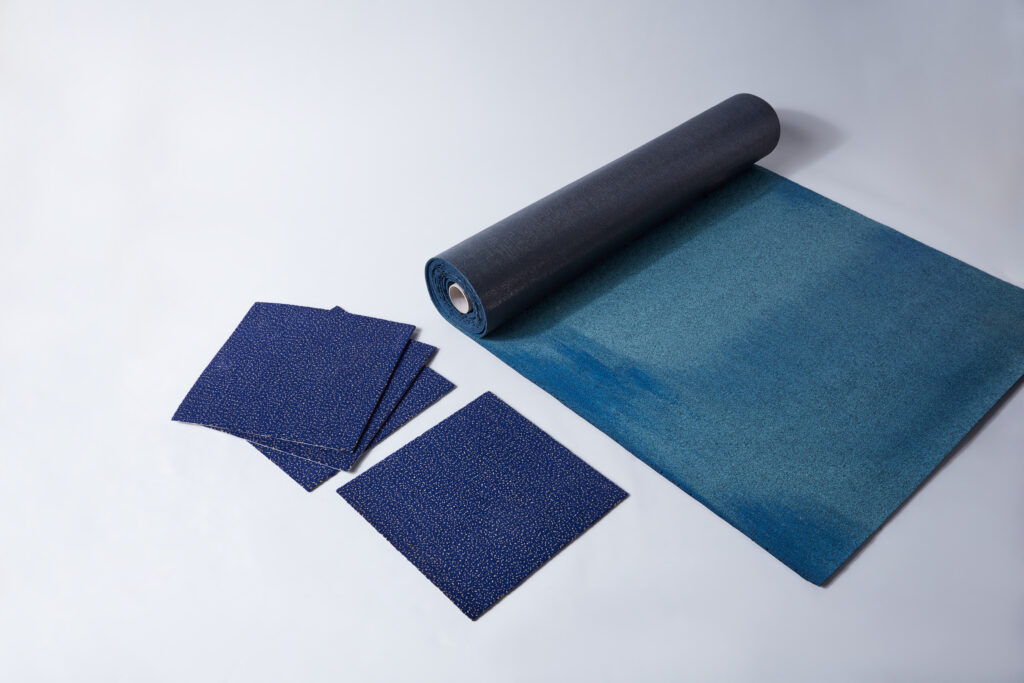

AHP waste is fed into the machine which sterilises it before being separated into three waste streams: cellulose, super absorbing polymers and mixed plastics.

“We take away the human waste part of the nappy and recycle nearly 100% of the AHP waste. About 50% of it is cellulose with about a quarter mixed plastic and another quarter is absorbent polymers,” said Dr Hatzopoulos. “We have a unique, patented technology, we can recycle very quickly and it generates a stream of secondary materials that are of high quality.”

The sustainability manager went on to say that the company has already tested using the mixed plastics produced from AHP in bottle caps for P&G washing detergents and is also investigating applications for the cellulose.

Treviso

Dr Hatzopoulos confirmed that the plant is going into full operational stage in Italy with waste partner, Contarina SpA. Treviso, where the plant is located, has a recycling rate higher than 85% and is often championed for its success although a factor in this is the adoption of ‘pay-as-you-throw’ model, in the area where the firm operates.

When responding to a question from the audience asking if P&G will offer free collections, Dr Hatzopoulos said: “It is something that we will have to discuss with local authorities. The local authorities in northern Italy located closest to our plant, they had already started a separate collection of nappies before we had even started thinking about a machine, for a number of reasons. When we came along with a machine, we realised this was a fantastic opportunity to partner together.”

The nappy recycling project is being backed by EMBRACED, an EU-funded group that promotes the recycling of AHP into high value materials such as fertilisers.

Zero waste

Delegates also heard about P&Gs larger sustainability goals which include the ambition to achieve zero waste to landfill for post-consumer waste.

The company also aims to double their use of recycled resin in plastic packaging by 2020.

Earlier this week, the company announced that it will sell a limited edition washing-up liquid bottle made from 100% recycled plastic and ocean plastic in 2018 (see letsrecycle.com. story).

Subscribe for free