And, the audience also heard of the importance of sustainability information which is increasingly becoming a norm for company reporting.

Kellogg’s

Annie Farrar, sustainable packaging lead, at Kellogg’s Europe, spoke about work to make the Pringles can more sustainable in terms of packaging content and recycling. This has been a product which has long been cited by Recycling Association chief executive Simon Ellin as hard to recycle, because it contained plastic, paper and metal.

Results of trials using more paper and card and eliminating the other materials had been quite positive, said Ms Farrar. She said that consumers liked it and found them easy to recycle, but on the Kellogg’s side there had been some damage to the product in the factory and distribution.

Because of this, work continues on the design of the can, she explained, “so we can ensure the freshness of the product and that ability to export across the world is still all the same, but is in a can that can be widely recycled.”

Ms Farrar emphasised that “We want to ensure it can be recycled in practice and in scale.”

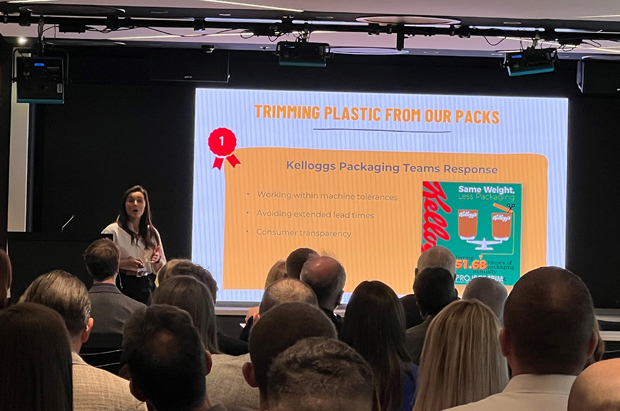

Pringles are not the only product packaging that is being tackled at Kellogg’s. Ms Farrar said: “We have our challenges elsewhere in Kellogg’s. One of the other projects we have worked on is removing the trimming plastic from the packaging of other products.”

Flavours

She explained there were 15 different food flavours involved in the project and how high value investments to change product lines, development times, and artwork changes had to be taken into account. The company has run eight large scale trials and, she noted, “our packaging team have done a fantastic job and worked within the current machine tolerances.

“We have also avoided extended lead times by keeping the materials the same. We are aware thought that consumers can be mistrustful of changes, and we know we need to call out what the changes are and ensure that there is transparency.”

The plastic trimming project has seen more than 51 tonnes of packaging removed annually, Ms Farrar told delegates.

Recycled plastic content… The availability is not very high at the moment and the cost is extortionate

However, one area where there is a challenge is around recycled plastic content. She remarked: “The availability is not very high at the moment and the cost is extortionate. How do we make it viable with the cost not passed on to the consumer and ensure it is right for the planet?”

She also expressed concern about the kerbside collection infrastructure which “is very poor at the moment. We need to ensure that the packaging we are designing today will run through these areas and consider how can we add value to those plastics so it can work circularly in those areas.”

Ms Farrar concluded by saying that Kellogg’s would welcome opportunities to work together with the recycling sector on new trials and solutions.

DS Smith

The Recycling Association conference was also addressed by Nick Thompson, materials development director for group research and development at the paper recycling, mill and packaging group DS Smith.

He spoke of innovation in packaging and how this has to meet a lot of needs – recycling is one of those.

The challenge is what we are replacing plastics with… we could end up with stickies in the paper machine

While one of the biggest challenges is the contamination that comes in with the fibre in paper for recycling, there are also problems with moisture and bacteria, said Mr Thompson. “Recyclability is a key challenge and we now have a laboratory at Kemsley to mimic the recycling and papermaking process”

Miscanthus

DS Smith is looking at process chemistries for biobased barriers which could replace plastic and how well they actually recycle. This includes miscanthus, straw, hemp and seaweed.

The materials development director said there was “a big trend” currently to try and remove plastic linings which are often made of several layers. “The trend is to reduce the number of layers, perhaps with adhesives, bio-adhesives, but main interest is in dispersion coating layers which are not always easy to recycle.

“The challenge is what we are replacing plastics with – if we replace it with something we can’t recycle, we could end up with stickies in the paper machine.”

There are successes, he said, and DS Smith has, working with its customers, got 380 million items of “problem plastics” off the shelf with corrugated alternatives, the company’s target is one billion.

Tetrapaks

He touched on Tetrapaks [cartons] and said that the recycling of fibre-based Tetrapak is a challenge. “We don’t like Tetrapaks at all… the fibre is there but we can’t get at it.” The fibre, he said, “gets stuck to the plastics” and that the cartons are “more problematic than coffee cups”.

Mr Thompson explained that specialised mills can handle Tetrapaks and that he saw the future in making cartons with dissolvable layers making it easier to recycle them. But, one of the problems in changing to different layers is that there are significantly more production costs and that they need to be a barrier against moisture, oil, gas and more, and that these solutions may not all be plastic free.

Ashurst solicitors

In terms of the big legislative picture, delegates heard from Eleanor Reeves, head of the environment and partner at Ashurst solicitors in London.

Ms Reeves, spoke of the environmental reporting requirements that businesses are increasingly having to face up to.

Bigger businesses are going to have to create net zero transition plans against a background of global issues that need global solutions, she explained. On the agenda were big issues such as tackling plastics and ‘forever chemicals’.

Sustainability reporting implications and actions are not just for big companies, she suggested as “these requirements will cascade throughout the economy.”

Mandatory

Looking at specific requirements, Ms Reeves said that new mandatory climate-related reporting will be there for larger AIM and private companies and LLPs who will have to produce ‘Non Financial and Sustainability Information Statements’. There are also requirements for corporate sustainability reporting.

Ms Reeves also mentioned the issue of greenwashing and how legal claims over this were on the rise, particularly in the United States.

Subscribe for free