And, the company’s CEO, Steve Miller, said he expects the technology to be in the UK in the first quarter of 2018.

Penn Waste

BHS provided new optical sorting and artificial intelligence (AI) technologies to the MRF operated by waste and recycling company Penn Waste.

The upgrade will boost the facility’s capacity by almost 30% from 35 to 45 tonnes per hour (tph), while at the same time increasing recovery, improving product quality, and reducing labour costs, BHS said.

The installation follows Penn Waste’s addition of a Nihot SDS 800i drum separator earlier in the year to increase capacity to purify glass.

According to BHS, with ongoing shifts in the material stream and increasing pressure from export markets for improved product quality, Penn Waste president and owner, Scott Wagner, made the decision to further invest in the facility to stay ahead of the competition.

Max

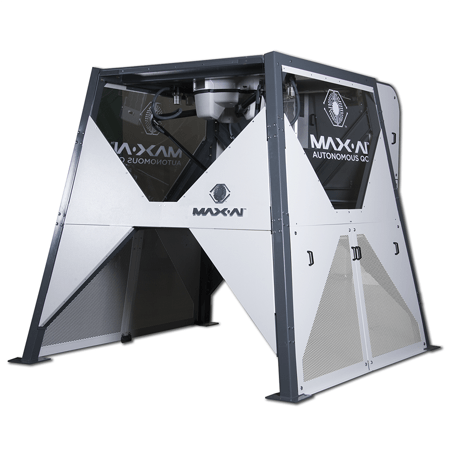

The $3.5 million investment includes three new NRT optical sorters and a Max-AI autonomous quality control (AQC) unit.

Max is an artificial intelligence system which identifies recyclables and other items for recovery. Max uses multi-layered neutral networks and a vision system to locate and identify objects. The technology is hoped to drive improvements in MRF design, operational efficiency, recovery, system optimisation, and maintenance.

In April, BHS unveiled Max and announced the unit had been installed at a MRF in Sun Valley, California. (see letsrecycle.com story)

At Penn Waste’s MRF, the NRT SpydIR optical sorter removes small cardboard boxes from the container line. The plant’s HDPE sorter was replaced by a larger NRT SpydIR, which is followed by a NRT ColorPlus that sorts the HDPE by color.

An eddy current separator increases UBC recovery. At the end of the line, the SpydIR® that had previously recovered HDPE was combined with an integrated MetalDirector™ that boosts the plant capture rate by recovering the last few plastic and metal containers that were missed by the main sorting process.

UK

When contacted by letsrecycle.com, Steve Miller, CEO of BHS said interest in MAX-AI is ‘developing quickly’.

In terms of timescale in bringing Max over to the UK, Mr Miller said: “It certainly is too late this year to think about having it installed this year. But, yes, in the first quarter of next year there will be multiple units.”

“The whole drive around Max-AI is to really industrialise the recycling process,” said Mr Miller. “I think it’s fair to say that when you look at the recycling process technology has continued to play a part in assistance, but they also have been dependent on manual labour and the industry really hasn’t been able to shake that.”

“We see Max really allowing the industry to move forward towards an automated environment.”

Mr Miller revealed that around 20 Max-AI units have been sold – some of those in Europe. He also said the company has verbal agreements for another half a dozen. It is understood some of these are with UK customers.

Quality

Mr Miller also discussed the company’s plans to launch a new model of Max next year which will be able to report on quality.

“This is a unit that will be able to characterise material in real time and report on quality and record exactly what material goes into a bunker.”

Mr Miller said with the demand for quality created by China and with the National Sword, “the ability to know what you’re producing and provide that information to your customers will be really important.”

Above: A video interview with Penn Waste’s director of recycling operations Tim Horkay, with footage of the upgraded system in action, including the new Max-AI

Districts

Earlier this year, BHS also announced a project to design, manufacture and install a MRF featuring its Max-AI for the Sanitation Districts of Los Angeles county (Districts), at the Districts’ Puente Hills MRF.

The system will process both commercial and residential streams – including dry commercial waste, commercial municipal solid waste, multifamily MDW and single stream recyclables. According to BHS, the system will increase the Districts’ processing capacity to 600 tonnes per day.

The system features a Max-AI in a quality control role on the PET that is recovered by the system’s NRT SpydIR®-T optical sorter.

Subscribe for free