However, Fortum has said that for the time being, the project is still in its early development stage and no investment decision has been made.

Launched today (2 December) and running until 27 January, the consultation aims to gather views before the Agency makes a final decision on the plant next year.

Finland-owned Fortum first applied for a permit to build the Kingmoor Energy Recovery Facility in 2020 (see letsrecycle.com story).

In an accompanying document, the Agency said the consultation gives it an opportunity to explain the thinking behind issuing a draft acceptance, including assessing the environmental impacts of the plant and impact on wildlife.

“We consider that, in reaching that decision, we have taken into account all relevant considerations and legal requirements and that the permit will ensure that a high level of protection is provided for the environment and human health,” the Agency said.

The consultation can be viewed here.

As with most plants coming onto the market, there has been some local opposition to the plant. The CRAIN (Carlisle Residents Against Incinerator) group has repeatedly tried to lobby to have the plant halted.

A spokesperson for Fortum added: “We are pleased to see that the Kingmoor environmental permitting process is moving forward. Once the permit has been granted we’ll be able to asses a way forward.”

Plant

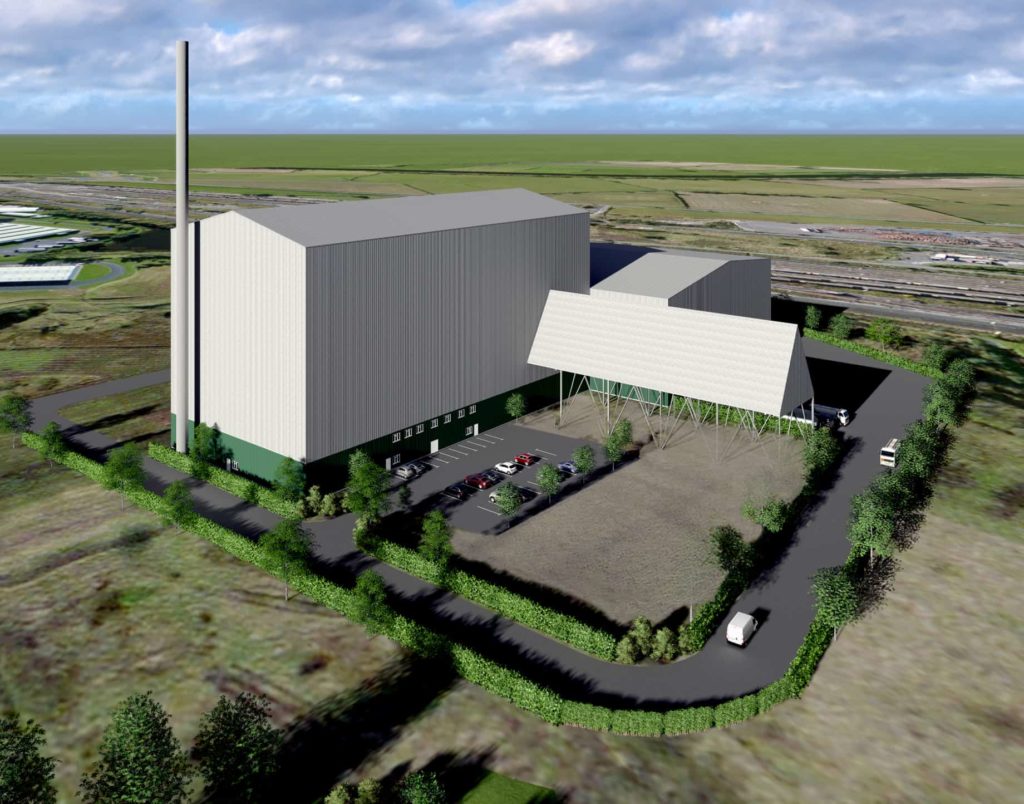

In the permit document, Fortum said the Kingmoor plant, located approximately 4-5 km north-west of Carlisle city centre, will consist of a single line incineration plant processing the incoming waste.

It said incoming waste would be inspected at the weighbridges against the agreed specification. Unacceptable waste such as large, bulky non-combustible items will be removed from the bunker for further inspection and quarantine, prior to transfer off-site to a suitable disposal or recovery facility.

The combustion chamber will utilise a conventional moving grate technology and will process approximately 250,000 tonnes a year. Emissions to air will be via a 70m high stack.

Bottom ash will be collected at the end of the combustion grate and falls into the discharger, before being regularly collected for recycling.

Air pollution control residues (APCr) will be sent to a suitably licensed hazardous waste landfill for disposal as a hazardous waste.

There has been no indication as to where the waste will be sourced from. If using UK RDF, it could further impact the export of material, which has been declining in England in recent years.

Subscribe for free