Last week, Environment Minister Michael Meacher praised the waste and lighting industry's fluorescent lamp recycling scheme – Sustainalite – which primarily recycles the mercury from lamps. But it has became clear that most of the “recyclable” materials are still landfilled because of insufficient markets.

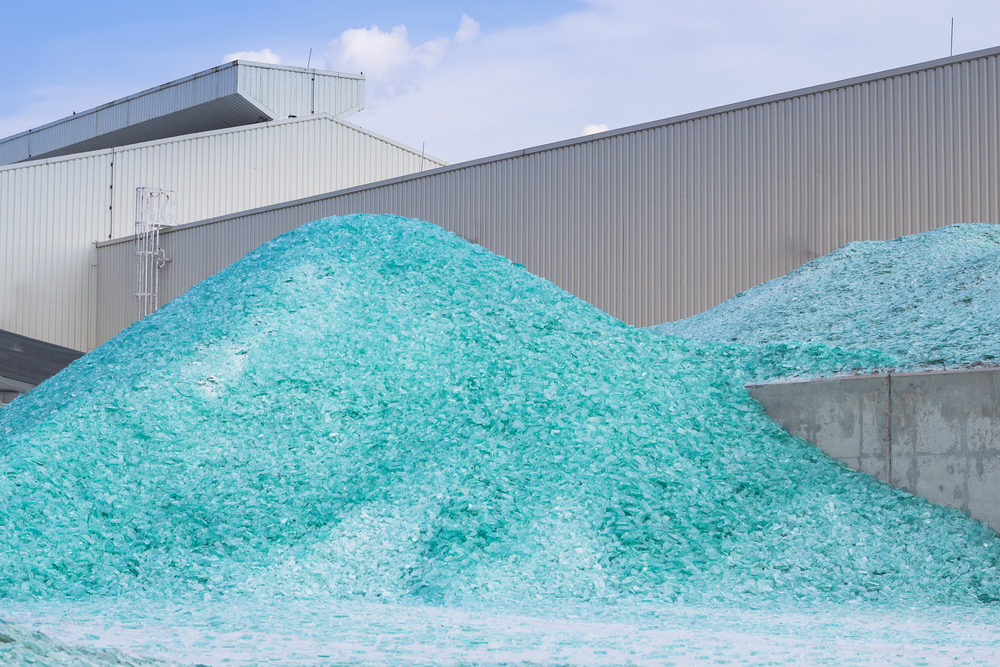

Glass accounts for 90% of the materials which make up fluorescent lights but finding reuse for the glass is difficult and most of it is currently landfilled.

WRAP now hopes to “close the loop” for lamp glass with the announcement of a project to research recycling opportunities for end-of-life lamp glass. This is one of WRAP's 3.6million projects to investigate new recycling technologies and market opportunities for recycled material. WRAP will provide 103,700, or 50%, of the funding for the glass lamp project which should be completed by January 2003.

The project, which is being carried out by British Glass in partnership with SLI Glass and Mercury Recycling, will identify high value end uses for the glass including being recycled into new lamps or other high value primary manufacturing processes.

Contamination

Andy Dawe, WRAP’s material sector manager for glass, said: “The concept of recycling this type of waste glass back into glass manufacture has been explored before, but issues such as contamination and cumulative compositional changes have limited any significant progress.

“This project brings together a company with an available secondary resource and a company capable of using it, and, providing the link between them, an organisation which can provide the technical expertise to make it happen. In addition, the overall environmental impact of this research work is likely to be particularly beneficial as the same glass could be recycled time and time again – a truly closed loop resource cycle.”

Last year, 100 million sodium, mercury and fluorescent lighting tubes were scrapped in the UK, which represents around 20,000 tonnes of glass. Around 80% of this could need to be recovered under the Waste Electrical and Electronic Equipment (WEEE) Directive and this will be very difficult to achieve if new markets are not found.

The main barrier which prevents lamp manufacturers from returning recovered glass from fluorescent tubes to the glass melter is uncertainty over the chemical composition of the glass and the environmental impact of any residual contaminants.

The study will investigate the chemical characteristics of the recovered glass, its consistency and reliability as a raw material for glass making. This will allow the technical implications of its re-use in lamp manufacture, and the potential environmental impacts of any trace contaminants such as mercury, to be assessed both from a manufacturing and a regulatory perspective. The final phase of the project will be a full-scale factory trial and the production of a case study for use by other manufacturing sectors using recovered glass.

Subscribe for free