The ESA, the trade association for the private waste sector, drafted the ‘Quality Standard for Recycled Plastics’ with support from its members. Also involved and supporting the standard are the British Plastics Federation (BPF), the Recycling Association and plastics recycling charity RECOUP.

Publication of the quality standard comes against a background of some industry concern over the interpretation of what is acceptable in terms of the export of plastics for recycling overseas.

Exporters can ship plastic waste from the UK as ‘green list’ material. The standard is focused on providing a set of criteria as to whether the ‘green list’ category is likely to have been met for export bales.

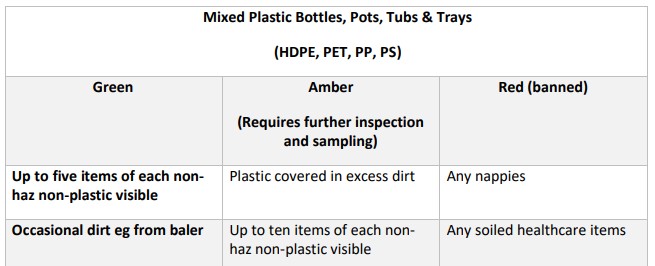

The standard covers the export of LDPE films and of mixed plastic bottles, pots, tubs and trays made from HDPE, PET, PP and PS.

It includes guidance for keeping records about each of the processes applied to the input materials, the care that should be taken to describe target materials and the amount of residual contaminants which can be present, among other things.

The ESA has also included a guide for visual inspections, classifying contaminants as ‘green’, ‘amber’ and therefore requiring further inspection, and banned ‘red’ items.

For mixed bottles, pots, tubs and trays, the guidance states that flies appearing when opening container doors would fall under the amber heading, for example. The guidance completely bans any nappies or “soiled healthcare items”.

Contamination

According to the ESA, the Department for Environment, Food and Rural Affairs (Defra) and the Environment Agency say materials destined for export should be “substantially free of contamination” and neither organisation defines a percentage limit for contamination. The ESA says this has resulted in “subjective judgements being disputed”.

Jacob Hayler, the ESA’s executive director, said: “Setting and delivering high standards for the sector is a strategic priority for the ESA and, by establishing a clear, objective, quality standard, we hope to bring consistency to output quality and provide a useful reference tool for both sellers and buyers of this material, supporting a market that remains vital to the UK’s circular economy.”

The ESA says all its members have agreed to adhere to the standard within the next year.

De minimis approach

Within the standard, the ESA says that certain recovery facilities may be able to handle materials with significant levels of contamination but, “for those materials intended for export, the contamination levels should be de minimis.”

To adhere to the European guidelines, the standard states, levels of residual contamination in baled post-consumer plastic exports must not exceed 2% by weight.

The ESA says the standard does not replace the position or requirements of regulators, who the trade association expect to continue to apply a subjective “de minimis” approach.

Members will collect and review inspection and monitoring data as they phase in the standard, the ESA says, and this will be used to develop and refine the requirements. And, the association says work is underway to create widely agreed commercial standards for other secondary materials.

‘Tangible standards’

Simon Ellin, the Recycling Association’s chief executive, said he was “delighted” to be part of a trade association partnership that delivered a workable standard all sectors of the industry can adopt.

“A key weakness in our day-to-day operations is the absence of tangible standards, but the standard we have now produced will not only help to improve quality, but should also facilitate clearer regulation, reduce risk and encourage investment,” he said.

Helen Jordan, senior recycling issues executive at the BPF, added: “Understanding the quality of material is key for the development of a circular economy and for effective plastic recycling to take place.

“The BPF supported the development of this quality standard for bales of plastic as it is essential that material destined overseas can be efficiently recycled.”

Collaborative

Stuart Foster, RECOUP’s CEP, said: “The opportunity to bring together previous guidance and support the development of a new relevant collaborative specifications document with the ESA, underpinned by practical current market requirements, was too good an opportunity to miss.

“We encourage the sector to make use of the new quality standards which will ensure the recycled plastic market demand and supply specifications are aligned.”

Related link

ESA quality standard for recycled plastics

Subscribe for free